EXPERTISE // SERVICES // METALLURGY AND APPLIED MECHANICS

Metal Fatigue and Fracture

Metal fatigue is one of the more common degradation mechanisms that WJE engineers consider while designing new infrastructure, assessing in-service performance, or investigating a failure. Characterized by fluctuating load applications originating from any combination of sources, fatigue can interact with other damage mechanisms or environmental conditions to create a hybrid failure. Leveraging state-of-the-art testing capabilities, a comprehensive metallurgical laboratory, and numerical analysis methods, our engineers can provide valuable insights to enhance the structural integrity of structures in the built world undergoing cyclical loading.

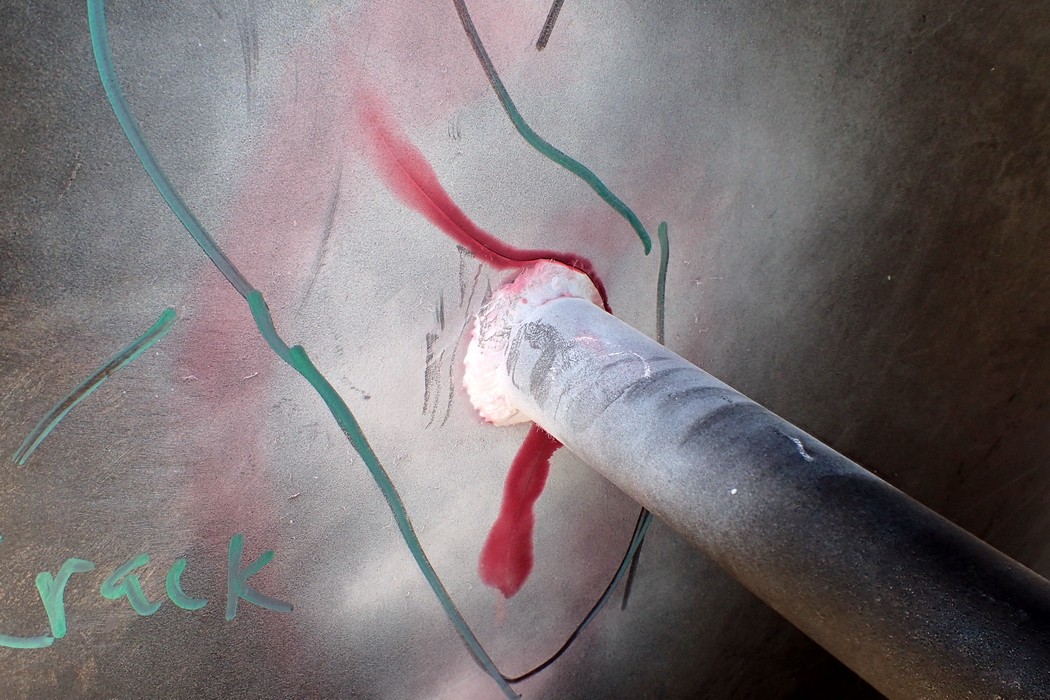

Structures are often subject to time-varying or alternating loads in-service that can result in fatigue accumulation and potential fracture. Although engineers design to minimize fatigue failures, periodic inspections can reveal crack-like flaws leading clients to ask WJE for recommendations on the necessity of repairs or other mitigation options.

Our engineers leverage in-house tools and expertise to understand the potential for fatigue failures in new designs. This often relies on numerical finite element (FE) modeling to calculate in-service stresses and to characterize the fatigue performance based on the specific loading scenario. In addition, we frequently perform forensic investigations when fatigue is identified to help understand the root cause of the problem and to design robust repairs to prevent similar issues.

By developing flaw acceptance criteria, optimizing designs to minimize alternating stresses, or assisting with materials selection and welding procedures to minimize fabrication defects, WJE assists clients with preventing in-service fatigue failures.

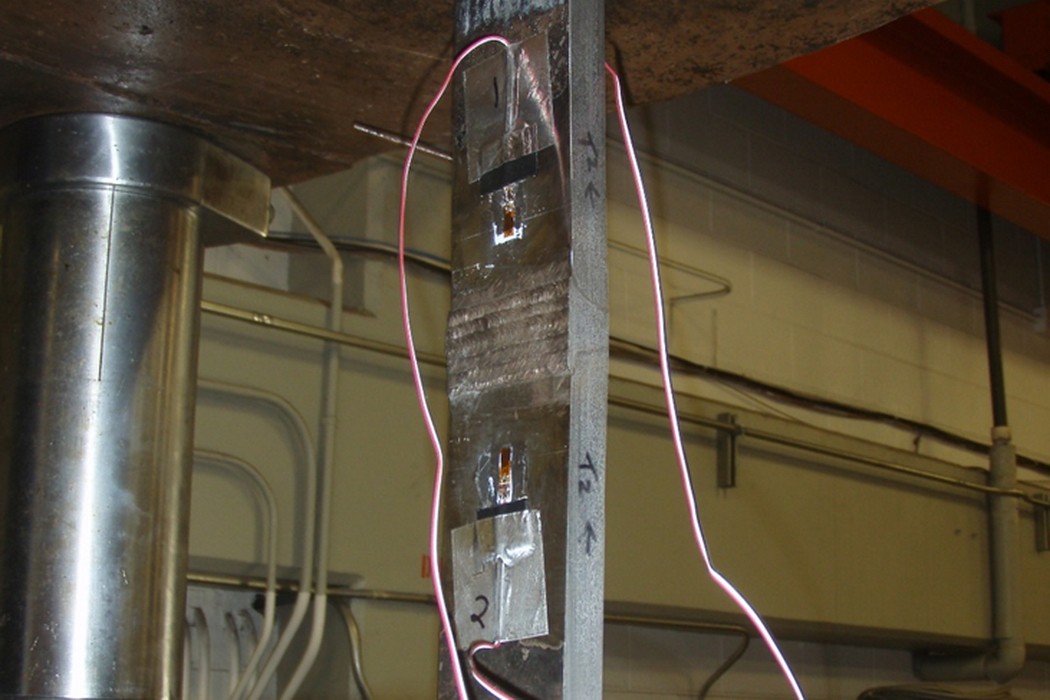

- State-of-the art structural laboratory

- High- and low-cycle fatigue performance testing

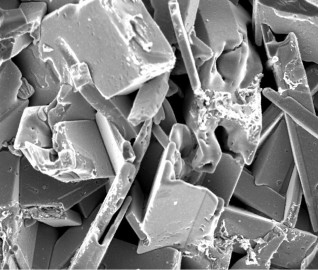

- Metallurgical laboratory

- Materials characterization testing

- Field metallography services

- Forensic investigation of failures

- Finite element analysis (FEA)

- Stress-cycle (SN) evaluation

- Fracture mechanics evaluation

RELATED INFORMATION

-

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics -

WJE's primary goal of performing a metallurgical failure analysis is to determine the root cause... MORE >Services | Metallurgical Failure Analysis

WJE's primary goal of performing a metallurgical failure analysis is to determine the root cause... MORE >Services | Metallurgical Failure Analysis -

At WJE, metals characterization is an important part of performing failure examinations and... MORE >Services | Metals Characterization

At WJE, metals characterization is an important part of performing failure examinations and... MORE >Services | Metals Characterization -

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center