EXPERTISE // SERVICES // METALLURGY AND APPLIED MECHANICS

Fracture Mechanics Assessment and Fitness for Service

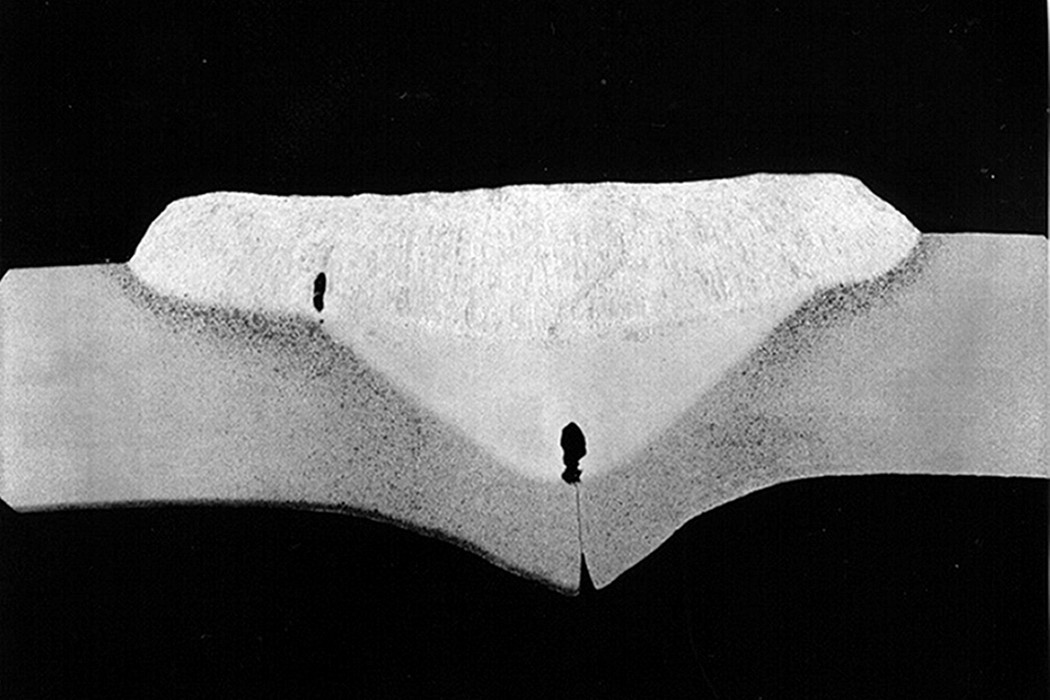

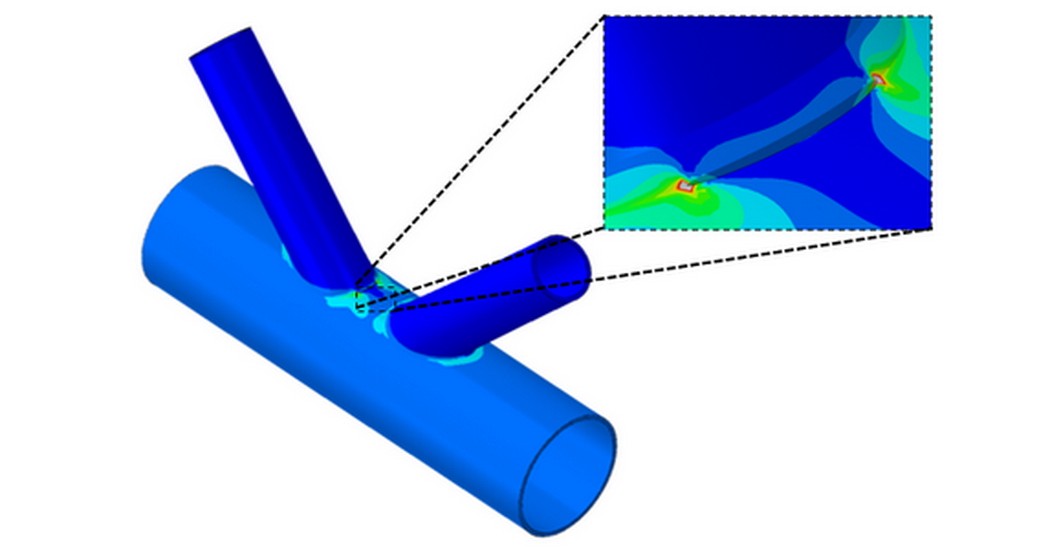

Having investigated and consulted on hundreds of metal structures and pressurized equipment facilities, our professionals are experienced providers of specialty evaluation services—like fracture mechanics assessments—for all types of new and existing metal components. We leverage the combination of recognized industry techniques, nonlinear finite element modeling, laboratory testing, forensic field investigation, metallurgy, field instrumentation, nondestructive testing (NDT) inspection, and years of experience to provide a rapid assessment and actionable solutions for the client.

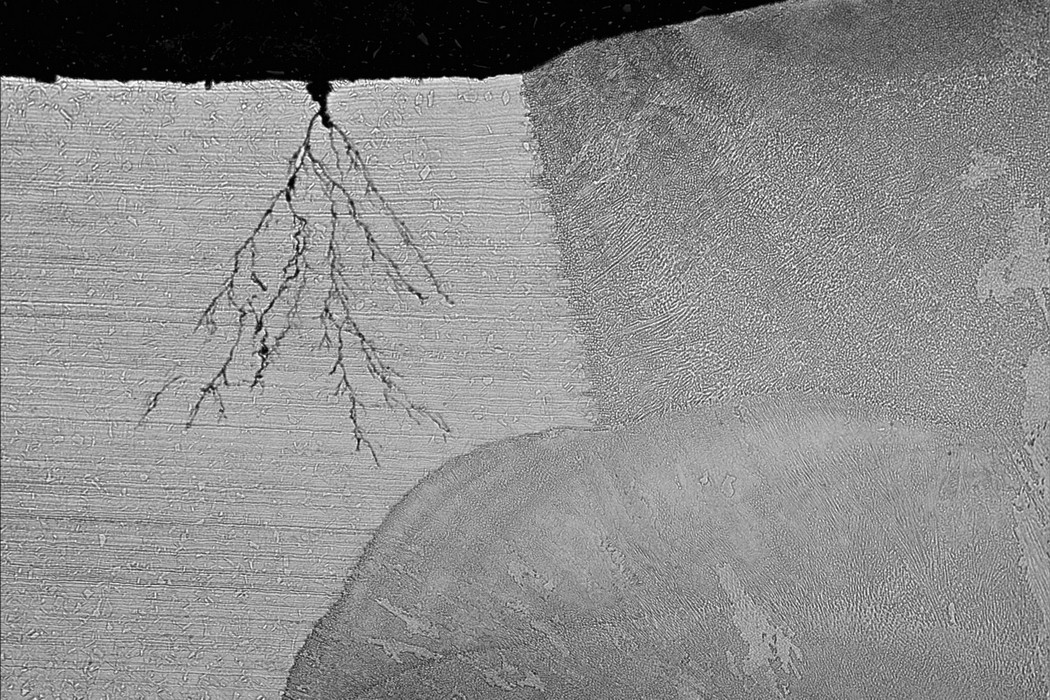

We help clients develop cost-effective solutions for their challenging new designs, existing infrastructure and facilities, and unexpected failures. We identify risks and safeguards to assist in preventing, controlling, and mitigating the effects of fabrication flaws, in-service deterioration (fatigue, corrosion, environmentally assisted cracking, creep), and unanticipated damage (third-party impact, fire, earthquakes). Our multidisciplinary approach combines knowledge of materials, inspection, fracture mechanics, nonlinear finite element modeling, testing, and years of experience to provide accurate and actionable solutions. We are world renowned for investigating failures and providing clients with accurate assessments. Our engineers provide services for bridges, buildings, cranes, dams, offshore structures, piping, pipelines, pressure vessels, proprietary components, tanks, and transportation structures.

Specific services we offer include developing fabrication flaw acceptance criteria, advising on materials and weld requirements, helping clients develop inspection programs, providing component testing programs for fracture and fatigue challenges, retrofits design, and independent third-party reviews.

- Engineering critical assessment to develop fabrication flaw acceptance criteria

- Estimation of remaining service life

- Estimation of remaining strength and ductility

- Third-party damage assessments

- Component testing

- Repair and retrofit design

- WJE CrackCalc™ (API 579 Fracture Mechanics Software)

- Peer review

- Forensic investigation

- Influence risk-based inspection, mechanical integrity, and structural integrity programs

- Industry recommended practices used: API 579, BS 7910, and R6

- Expert testimony

RELATED INFORMATION

-

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics -

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center -

Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing

Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing -

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy