EXPERTISE // SERVICES // METALLURGY AND APPLIED MECHANICS

Metals Characterization

Metals characterization is the process of examining and measuring the microstructural features of a metal, its physical properties, and the ways they relate. Here, metals characterization is an important part of performing failure examinations and understanding what can be done differently to ensure the integrity of the overall system going forward. Microstructural features in metal alloys include grain size, structure, orientation, alloying elements, phases, and intermetallic inclusions. The resulting physical properties include hardness/hardenability, tensile properties, toughness, appearance, and corrosion resistance to environments and chemicals. We utilizes a variety of in-house laboratories to perform hardness, tensile, and material toughness testing methods. The three most common techniques used to measure and evaluate metals are microscopy, spectroscopy, and macroscopic testing.

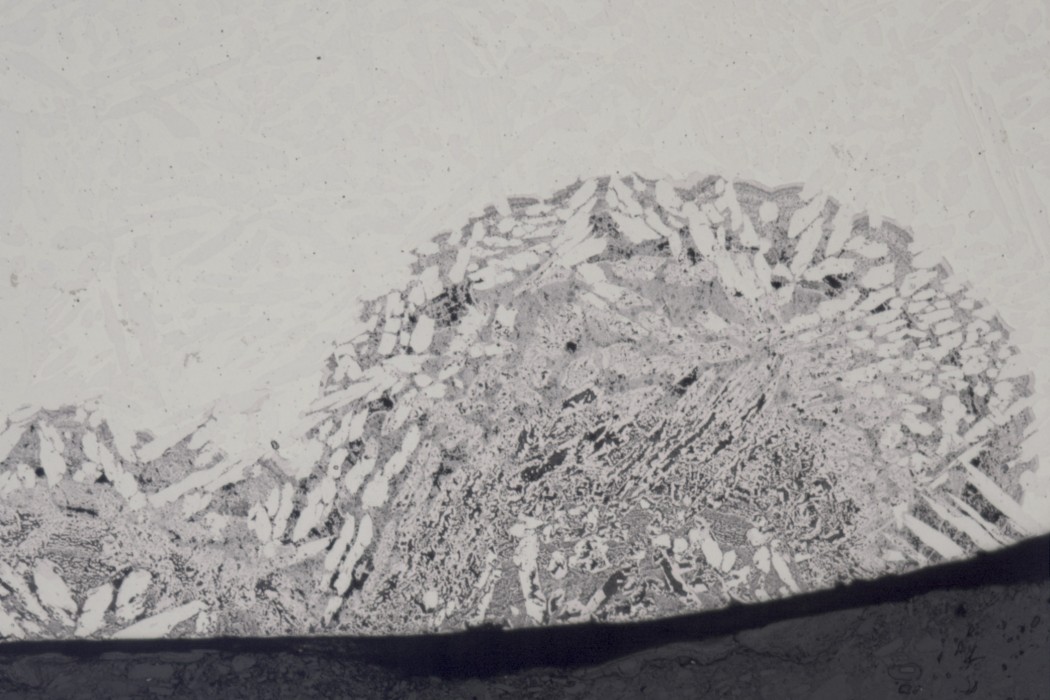

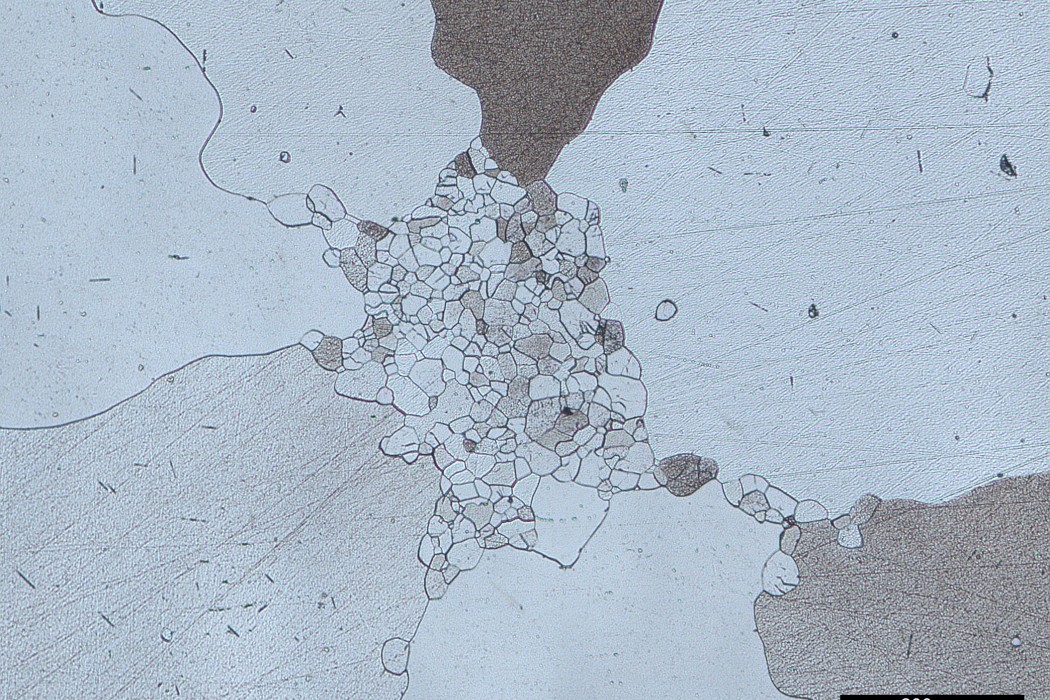

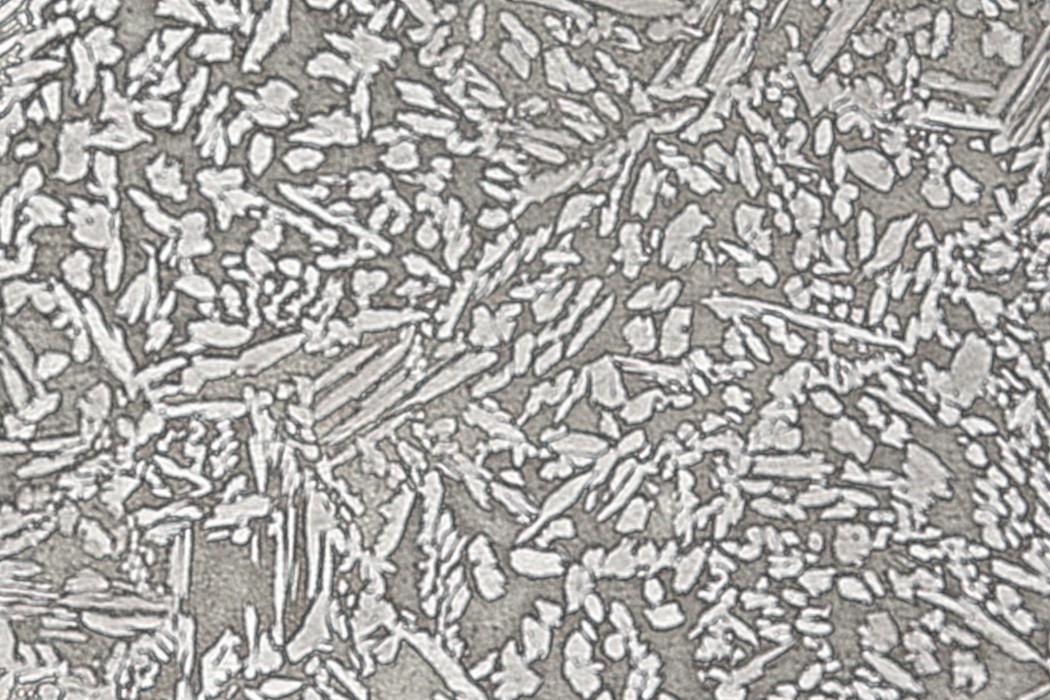

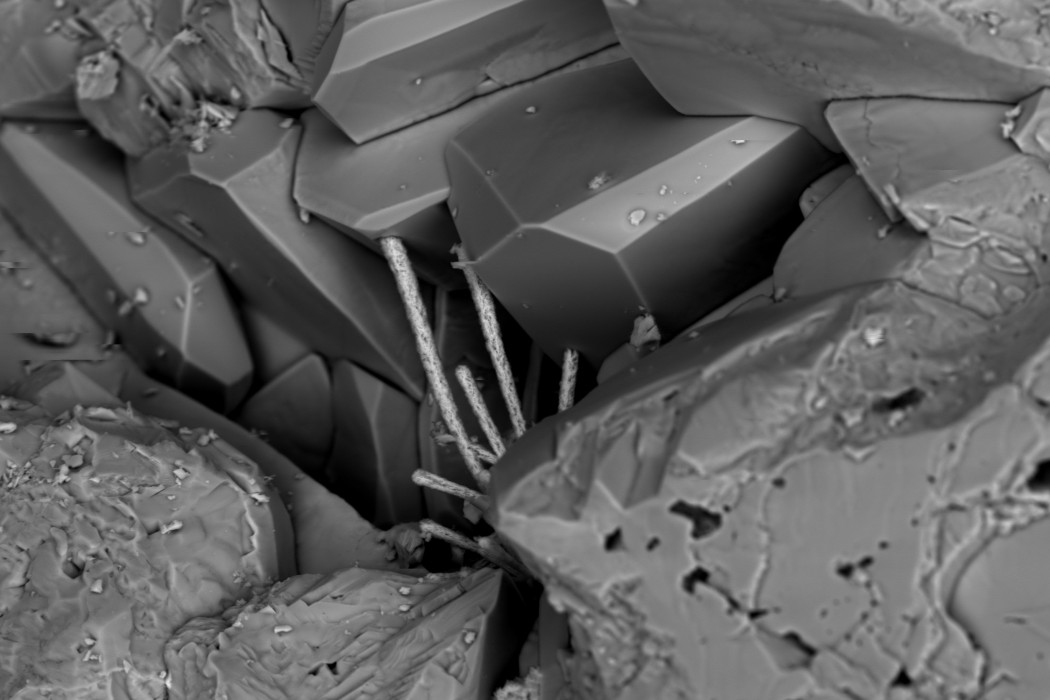

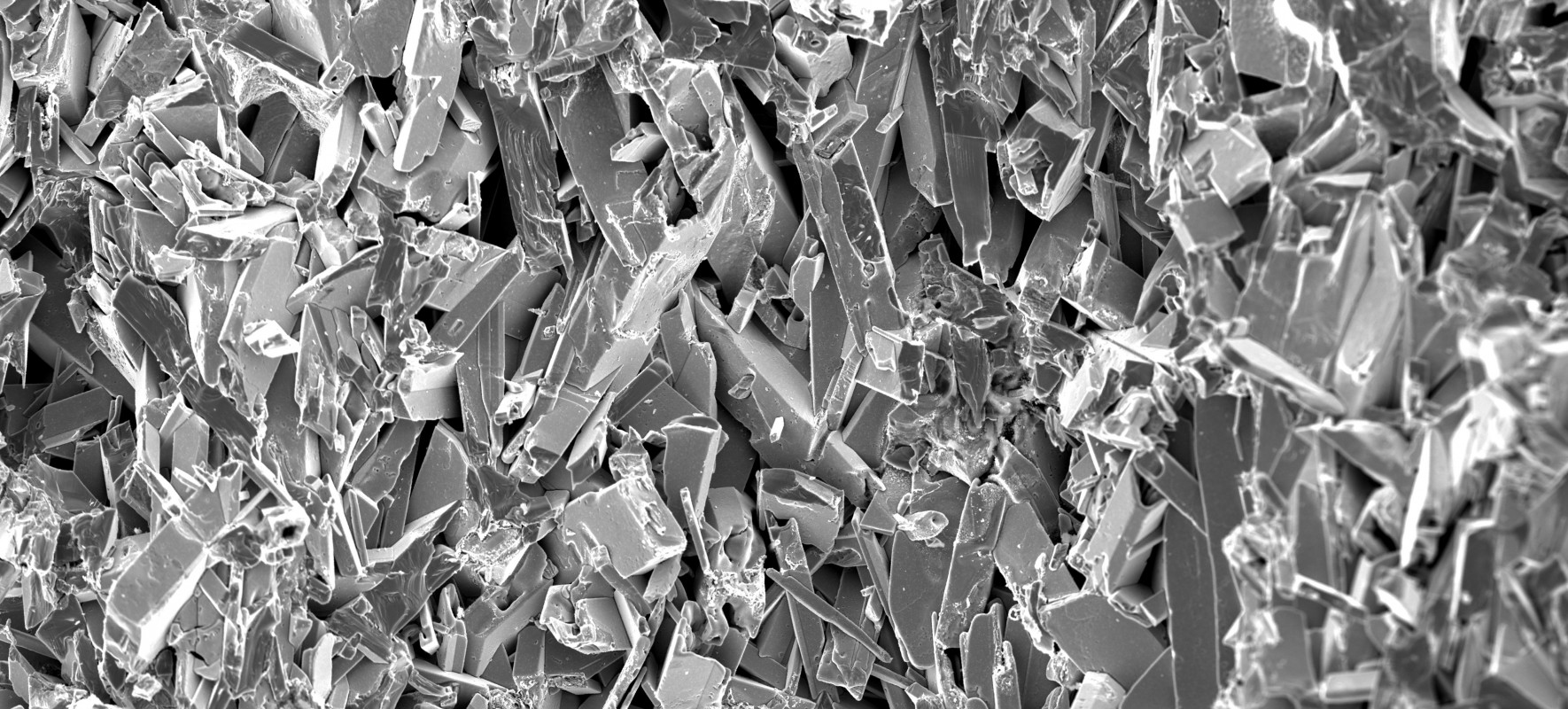

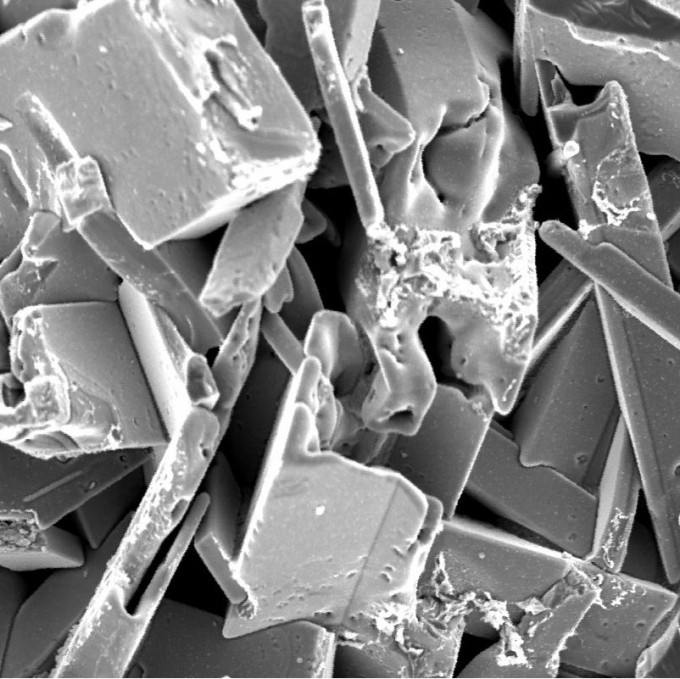

Optical and Scanning Electron Microscopy

We use optical microscopy and scanning electron microscopy (SEM) to examine microstructural features and fracture characteristics in both low- and high-magnification. Analysis of the grain structure provides insight into the heat treatments that a metal alloy may have undergone and can show any phases or inclusions that could be detrimental to the performance of the material in service.

Spectroscopy

Spectroscopy studies the relationship and interaction between a material and electromagnetic radiation. We utilize various forms of spectroscopy to determine information relating to the chemical composition or species present. Optical emission spectroscopy (OES) is a spark emission method to determine the chemical composition of a metal alloy with high accuracy, precision, and low detection limits.

Macroscopic testing

Macroscopic testing characterizes the physical properties of a material to provide insight as to how a material will perform in service. Other methodologies include energy-dispersive x-ray spectroscopy (EDS), x-ray fluorescence (XRF), Fourier transform infrared spectroscopy (FTIR), thermogravimetric analysis (TGA), and differential scanning calorimetry (DSC).

- Differential scanning calorimetry (DSC)

- Energy-dispersive x-ray spectroscopy (EDS)

- Fourier transform infrared spectroscopy (FTIR)

- Hardness testing

- Macroscopic testing

- Mechanical testing

- Metallography

- Optical emission spectroscopy (OES)

- Scanning electron microscopy (SEM)

- Surface profilometry

- Thermogravimetric analysis (TGA)

- X-ray fluorescence (XRF)

RELATED INFORMATION

-

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics -

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy -

WJE metallurgical and welding consulting engineers have extensive experience in the... MORE >Services | Metallurgical Consulting

WJE metallurgical and welding consulting engineers have extensive experience in the... MORE >Services | Metallurgical Consulting -

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center