EXPERTISE // SERVICES // METALLURGY AND APPLIED MECHANICS

Metallurgical Failure Analysis

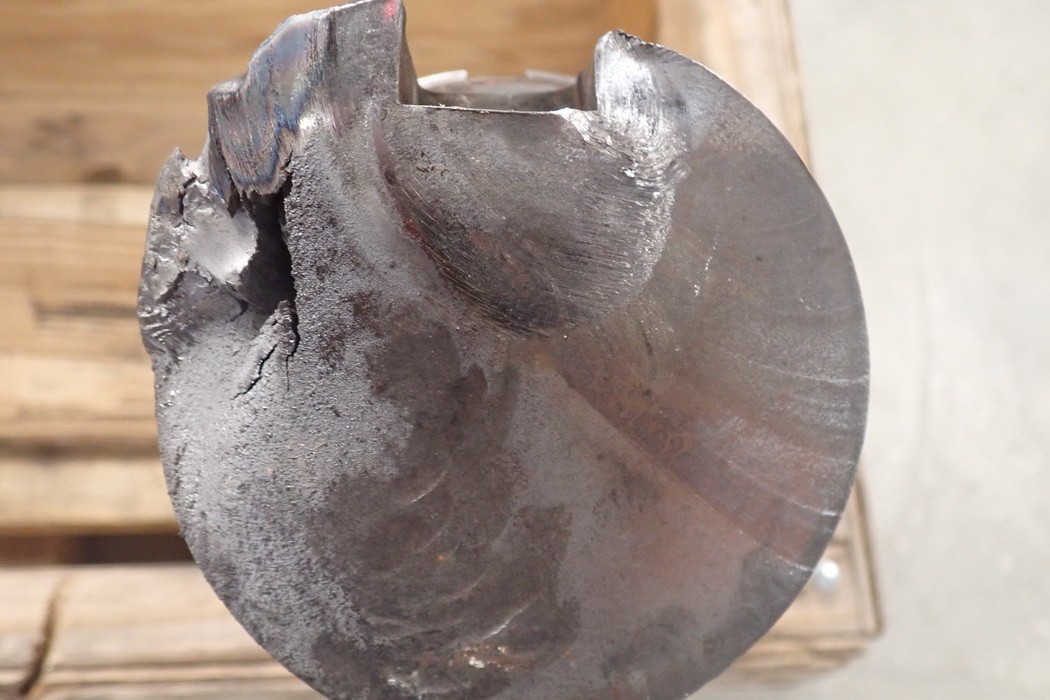

When a part or component breaks or fails to function in its intended purpose, the first questions usually are “Why or how did it break or fail?” A metallurgical failure analysis strives to answer these questions by utilizing a focused combination of observation and analytical techniques. Failed parts or components are scrutinized to identify features and/or material conditions that identifying causation. Once causation can be determined, this information is used to identify ways to mitigate future occurrences.

WJE's primary goal of performing a failure examination is to determine the root cause of the failed component and provide information regarding corrective actions and implementation to mitigate the possibility of future failures. This involves examining fracture surfaces, corrosion deposits, or material characteristics and comparing the observations with background information such as known service conditions (applied stresses, temperature, or exposed chemicals), mill test reports and associated specifications, or any relevant background data regarding the failed component.

WJE’s metallurgy and applied mechanics engineers use highly technical instruments in our state-of-the-art Janney Technical Center to analyze these samples. Our metallurgical experts use this information to determine if there was a material, manufacturing, or design defect, misuse, or any environmental factors that lead to the failure of the metal component, helping our clients determine their best point of action to mitigate the issue.

- Stress failures

- Mechanical overload

- Cracking

- Fatigue

- Creep rupture - Corrosion failures

- Uniform

- Pitting

- Erosion-Corrosion - Environmental exposure

- Embrittlement

- High-temperature exposure - Stress and corrosion failures

- Stress corrosion cracking

- Corrosion fatigue - Materials-related failures

- Composition

- Material flaws

- Heat treatment

- Weld - WJE CrackCalc™ (API 579 Fracture Mechanics Software)

RELATED INFORMATION

-

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics -

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy -

As part of our focus on the built world, WJE has the capabilities and expertise to help... MORE >Services | Upstream Oil and Gas

As part of our focus on the built world, WJE has the capabilities and expertise to help... MORE >Services | Upstream Oil and Gas -

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center