Experience

Robert Warke joined WJE in 2017 with a diverse thirty-year background in industry and industrial consulting, forensic investigation, applied research and development, and engineering education. He is a metallurgical generalist, but has specific expertise in the analysis, diagnosis, prediction and prevention of failure, and in the physical and welding metallurgy of ferritic and austenitic steels. Mr. Warke also has significant experience in the fatigue and fracture analysis of welded and other structures and components, and in the application of probabilistic methods to the assessment of fitness for service.

Mr. Warke’s experience spans a variety of industries including: oil and natural gas production, processing, storage and transmission; railroads, rail cars and locomotives; agricultural, construction and mining equipment; automotive and military vehicles; aircraft; building, bridge and ship structures; metal ore processing; steel mills and foundries; fossil fuel and nuclear power plants; building materials, pulp and paper, chemical, gas liquefaction, and food production facilities.

Mr. Warke has been an active member in the technical community, having served on a variety of technical committees, authored or coauthored sixteen papers and two handbook chapters, and presented at numerous conferences and seminars. As a full-time professor at LeTourneau University, he taught courses and supervised research and design projects in materials and welding engineering, and served as faculty advisor to the joint AWS/ASM/TMS student chapter.

REPRESENTATIVE PROJECTS

Failure/Damage Investigations

- Coal Mine - Rural WV: Coal silo cone failure due to attachment weld corrosion

- Solar Farm - Uvalde, TX: Weld-related cracking in solar panel mast foundations

- University Dormitory - TX: Corrosion of brass fittings and cracking of crimp rings in PEX potable water system

- International Airport - Indianapolis, IN: Fractured embed plate welds on collapsed panel in multistory parking structure

- Wind Farm - Tyler, MN: Wind turbine gearbox failure

- I-75 Toll Lanes - Atlanta, GA: Collapse of new retaining wall due to soil nail fracture

- Hospital - Pikeville, KY: Weld-related cracking in double-tee beam flange connectors in multistory parking structure

- High-Rise Hotel - Austin, TX: Collapse of new portico due to failure of rebar-to-embed plate welds

- Motorcycle Dealership - OR: Fracture of steering column in all-terrain vehicle

- Building Products Manufacturer - Carthage, TX: Weld-related structural collapse of inlet dampers in ductwork to OSB chip dryer *

- Oil Sands Bitumen Upgrader - Rural AB, Canada: Girth weld cracking in heavy-wall hydrotreater vessel *

- Coal-Burning Power Plant - Rural TX: Fragmentation of boiler exhaust gas recirculation fan *

Welding and Weld Repair

- Port of Houston - TX: Underwater rebar welding procedure specification (WPS) for wharf repair project

- Oil Refinery - Sinclair, WY: Embedded support for maintenance turnaround

- High-Rise Office Building - Chicago, IL: WPS for aluminum roof davit

- Oil Refinery - Mount Vernon, IN: WPS review for process equipment repairs and pipeline hot taps

- Power Plant - Rural IN: Weld repair procedure for corroded coal silo cones*

- Various Locations: Weldability assessment and WPS development for repair and modification of early 20th-century steel structures

- Various Locations: Mitigation of weld-related corrosion in stainless steel piping and tankage

Engineering Critical Assessment

- Pipeline Research Council International: Reliability-based methods for assessing flawed, strength-mismatched girth welds in pipelines subject to ground movement hazards *

- Public Utilities - CA: Probabilistic fracture and plastic collapse assessments of 1930s-era gas pipelines subject to seismic deformation and slope instability *

- Gas Research Institute: Metallurgical evaluation of mechanically damaged pipes for enhanced assessment criteria *

* With previous firms

Professional Affiliations

American Welding Society

ASM International

The Minerals, Metals & Materials Society

Registrations

Professional Engineer in TX

Education

LeTourneau University

Bachelor of Science, Welding Engineering, 1986

Illinois Institute of Technology

Master of Science, Metallurgical and Materials Engineering, 1994

RELATED INFORMATION

-

Learn about "dirty" steel and its potential deleterious effects on vintage building renovations. MORE >Webinars | Vintage Building Renovations: How to Avoid Costly Pitfalls Due to “Dirty” Steel

Learn about "dirty" steel and its potential deleterious effects on vintage building renovations. MORE >Webinars | Vintage Building Renovations: How to Avoid Costly Pitfalls Due to “Dirty” Steel -

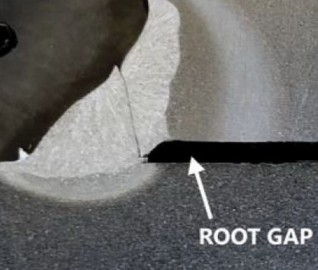

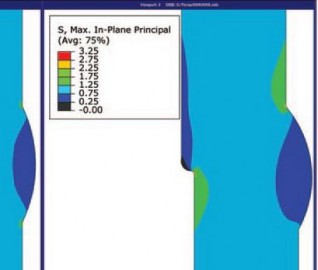

There are two phenomena associated with the root gap (or root opening) at the fillet weld root... MORE >Articles | Root Opening Considerations for Fillet Welds

There are two phenomena associated with the root gap (or root opening) at the fillet weld root... MORE >Articles | Root Opening Considerations for Fillet Welds -

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics -

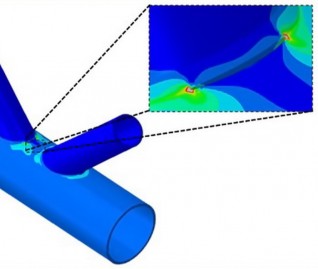

Uncovering challenges and best practices to prevent failures caused by misalignment MORE >Articles | Circumference Weld Misalignment: Causes, Allowable Limits, and Mitigation

Uncovering challenges and best practices to prevent failures caused by misalignment MORE >Articles | Circumference Weld Misalignment: Causes, Allowable Limits, and Mitigation -

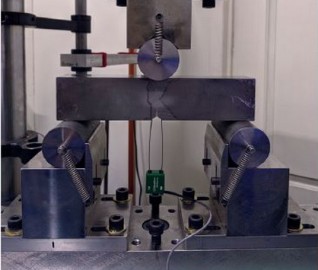

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center -

Learn the benefits of employing an optional strategy to evaluate flaws when welding to AWS D1.1 MORE >Articles | Recommendations for Developing Alternative Flaw Acceptance Criteria for Structural Steel Welds

Learn the benefits of employing an optional strategy to evaluate flaws when welding to AWS D1.1 MORE >Articles | Recommendations for Developing Alternative Flaw Acceptance Criteria for Structural Steel Welds -

WJE fracture mechanics consultants have provided fracture mechanics assessment and fitness for... MORE >Services | Fracture Mechanics Assessment and Fitness for Service

WJE fracture mechanics consultants have provided fracture mechanics assessment and fitness for... MORE >Services | Fracture Mechanics Assessment and Fitness for Service -

As part of our focus on the built world, WJE has the capabilities and expertise to help... MORE >Services | Upstream Oil and Gas

As part of our focus on the built world, WJE has the capabilities and expertise to help... MORE >Services | Upstream Oil and Gas