WJE PROJECTS

Babson College Globe

CLIENT |

Feingold Alexander Architects |

LOCATION |

Wellesley, MA |

Mechanical Inspection of Support and Operating Machinery of Globe

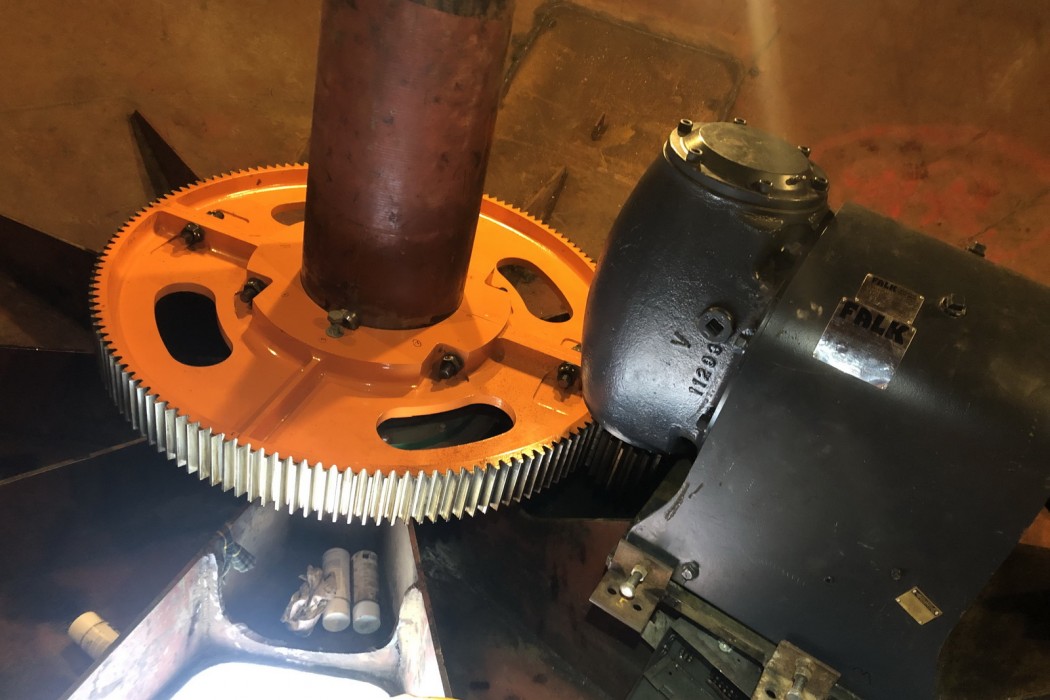

WJE was retained to perform an inspection of the support and operating machinery of the Babson College Globe. The globe is comprised of an approximately 28-foot-diameter steel sphere, which is supported in roller bearings on an inclined trunnion. It was known that at some point the lower trunnion bearing failed, causing damage to the operating machinery.

BACKGROUND

Located on the Babson College campus, the 28-foot-diameter, 25-ton Babson College Globe was originally engineered to rotate on its own axis. The operating machinery rotates the globe about the trunnion and rotates the trunnion and support structure to simulate the movement of the Earth as it orbits the sun. At the time of WJE's mechanical inspection, the historic heavy movable structure was undergoing a yearlong donor-funded restoration.

SOLUTION

WJE performed a mechanical inspection to assess the existing condition of the globe machinery, developed a recommended scope of work to rehabilitate the globe to restore operation, and provided budgetary cost estimates for completing the rehabilitation. The inspection and subsequent investigation determined that the root cause of the lower bearing failure was improper selection of the bearing type (spherical roller bearing used in an axial thrust application) and inadequate lubrication. WJE developed a rehabilitation design that replaced the original lower bearing with a new spherical roller thrust bearing (SRTB).

Due to the lack of original design or shop drawings and an aggressive construction schedule to refurbish and relocate the globe to a new park setting in time for their centennial celebration, Babson College implemented the rehabilitation using the design-build approach. WJE engineers developed conceptual design details for the new and rehabilitated machinery components and worked collaboratively with the contractor afterward to develop the shop drawings and means and methods to safely jack and remove the globe from its trunnion, reinstall the globe on the trunnion with the new bearings, and restore the operating machinery to operating condition. WJE provided engineering support services through completion of the construction work.

RELATED INFORMATION

-

We are an industry leader in the design, inspection, and repair of heavy movable structures MORE >Services | Heavy Movable Structures

We are an industry leader in the design, inspection, and repair of heavy movable structures MORE >Services | Heavy Movable Structures -

Our professionals deliver practical repair and rehabilitation services that maximize the... MORE >Services | Repair and Rehabilitation

Our professionals deliver practical repair and rehabilitation services that maximize the... MORE >Services | Repair and Rehabilitation -

Our design professionals assist in making the overall project design achievable, maintainable,... MORE >Services | Design-Build

Our design professionals assist in making the overall project design achievable, maintainable,... MORE >Services | Design-Build