WJE PROJECTS

U.S. Air Force Academy Cadet Chapel

CLIENT |

AECOM, on behalf of the U.S. Air Force Academy |

LOCATION |

Colorado Springs, CO |

Recladding Design Phase

After five decades of persistent water leaks that were not stopped by multiple repair campaigns, the Air Force determined a complete removal and replacement of the exterior cladding was the only repair capable of correcting the underlying deficiencies in the Cadet Chapel’s original design and construction. WJE partnered with AECOM, who held the Air Force design phase contract, to serve as their consultant responsible for the design of the new cladding.

BACKGROUND

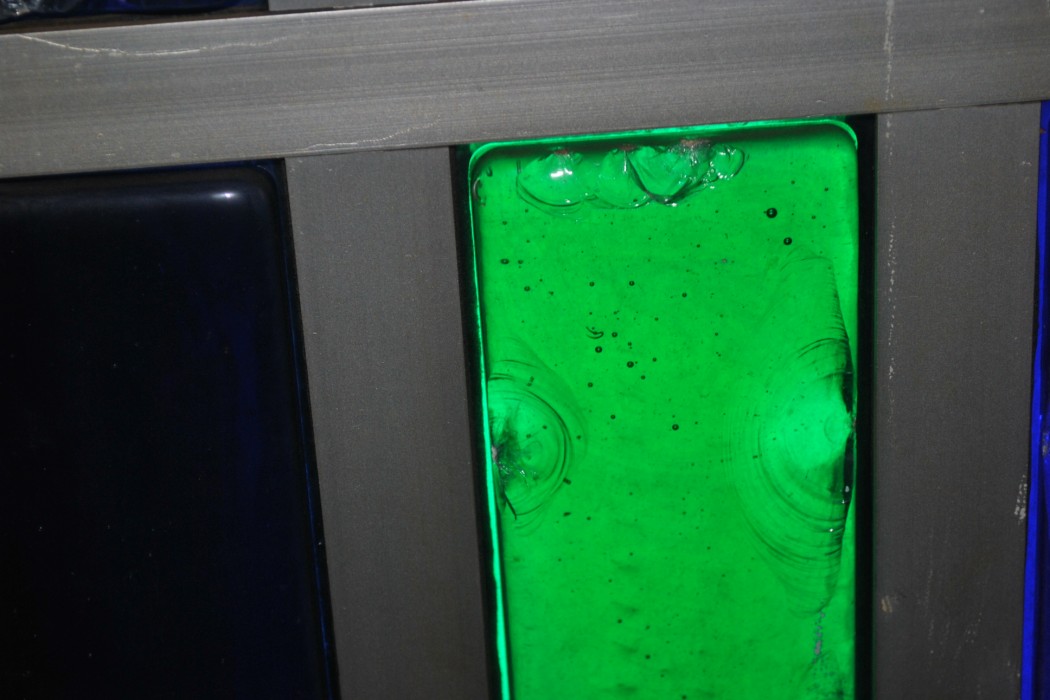

The U.S. Air Force Academy Cadet Chapel, located on the Academy base just outside of Colorado Springs, was designed by Walter Netsch and the architectural firm of Skidmore, Ownings and Merrill and completed in 1963. The 150-foot-tall chapel with its seventeen spires is the most visited man-made attraction in the State of Colorado. It houses four unique interior chapels, with the upper-level Protestant Chapel shown. Despite numerous repair attempts, the Chapel has leaked since its completion. The primary problem is that the cladding was designed as a single-skin barrier system with no redundancy if any of the myriad joints failed.

SOLUTION

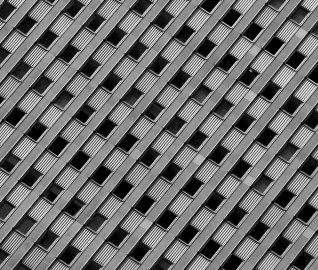

The design concept involved a rain screen cladding with a redundant dual-skin barrier to mitigate water leakage. Before designing the rain screen cladding, WJE first needed to understand and structurally analyze the existing steel tetrahedron-framed structure. WJE monitored the building to measure actual structural behaviors over a one-year timeframe. Along with the year-long monitoring, WJE created a detailed SAP model based on original steel shop drawings. WJE then hired a wind consultant to perform a wind tunnel test since the building’s geometry, combined with highly localized winds at the front-range of the Rockies, precluded a conventional assessment of design wind loads.

With an understanding of the structural behavior, WJE proceeded with the cladding design. WJE developed 3D CAD models to understand the complex geometries of all cladding elements. The rain screen design proposed an inner aluminum skin serving as the air and water barrier, while the exterior, open-jointed anodized aluminum cladding is the aesthetic match to the original. The extra wall thickness that resulted from the dual-skin design was tucked within the interstitial space within the tetrahedron structure and will not be seen once construction is finished. The cadet area, including the chapel, is on the National Register of Historic Places, and all final appearances are intended to match the 1963 original.

RELATED INFORMATION

-

Our professionals balance the need to provide practical, long-term solutions with the ability to... MORE >Services | Historic Preservation

Our professionals balance the need to provide practical, long-term solutions with the ability to... MORE >Services | Historic Preservation -

We engage a full suite of state-of-the-art instrumentation and monitoring capabilities to test... MORE >Services | Instrumentation and Monitoring

We engage a full suite of state-of-the-art instrumentation and monitoring capabilities to test... MORE >Services | Instrumentation and Monitoring -

When the integrity or condition of a structure is in question, clients rely on us for answers MORE >Services | Structural Engineering

When the integrity or condition of a structure is in question, clients rely on us for answers MORE >Services | Structural Engineering -

We understand the myriad challenges faced by building owners and managers, and we're committed... MORE >Markets | Buildings

We understand the myriad challenges faced by building owners and managers, and we're committed... MORE >Markets | Buildings