WJE PROJECTS

Mystic River Bascule Bridge

CLIENT |

TranSystems |

LOCATION |

Stonington, CT |

Mechanical Engineering Services for Rehabilitation

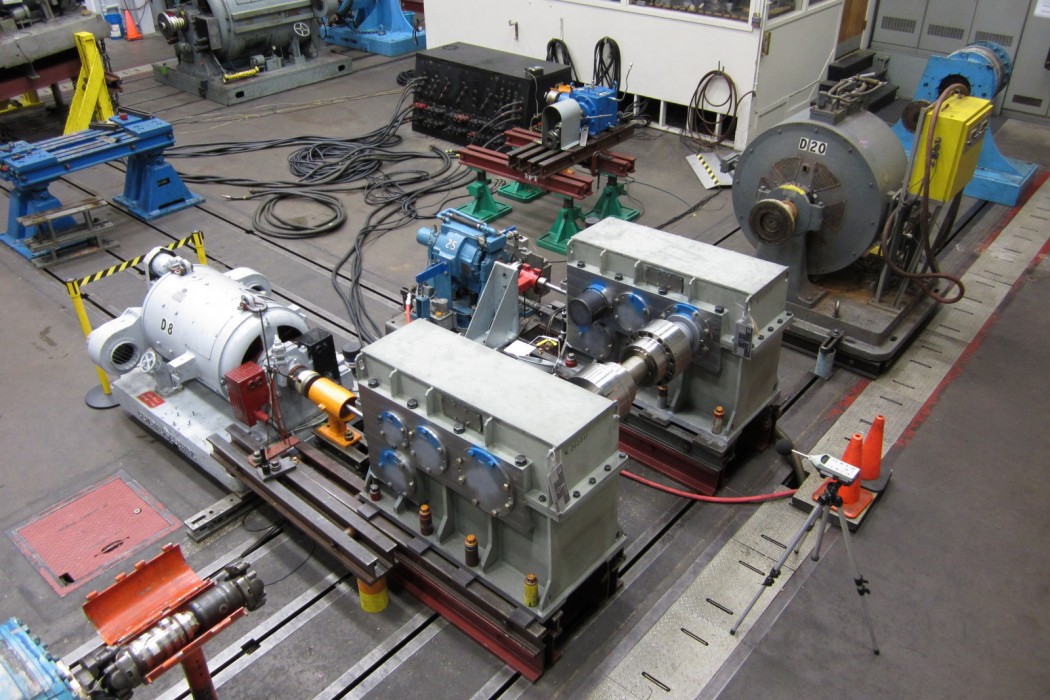

WJE provided mechanical engineering services for the rehabilitation of Mystic River Bascule Bridge from inception through completion. Services included a scoping inspection; complete rating of all mechanical machinery; development of a Bridge Design Report; preparation of plans, specifications, and cost estimates for the design of all machinery; and construction services.

BACKGROUND

The Mystic River Bascule Bridge is a historic single-leaf bascule bridge that spans the Mystic River in Mystic, Connecticut. The bridge was designed by Thomas Ellis Brown, the former chief engineer of Otis Elevator Company, and built in 1920 by the J. E. FitzGerald Construction Company of New London, Connecticut. The bridge’s movable span is 85 feet wide by 218 feet long. It employs two concrete-filled counterweights and is driven by two direct current motors. The bridge is owned and operated by the Connecticut Department of Transportation.

SOLUTION

WJE’s scoping inspection identified major settlement of the substructure, resulting in misalignment of the upper balance truss and span drive machinery relative to the bascule span. Subsequently, WJE’s design services expanded to include rehabilitation to correct this misalignment, including replacement of the primary support components for the balance truss and balance link components.

WJE's design plans provided complete details of all mechanical components, including the critical design of all base plates, to ensure proper support for all mechanical components. The rehabilitation design provides new span drive machinery to comply with current AASHTO requirements, improved efficiency, and reduced maintenance requirements.

Construction services for the bridge rehabilitation were extensive and included partnering meetings; review of shop drawings; approval of machinery installation and alignment procedures; shop inspection; oversight of critical machinery alignment; approval of the entire mechanical installation prior to startup; and oversight during the initial opening, including the monitoring of the machinery loads. The mechanical construction work was completed over two winter closure periods, and the bridge was opened on schedule at the end of each of the closures.

RELATED INFORMATION

-

We are an industry leader in the design, inspection, and repair of heavy movable structures MORE >Services | Heavy Movable Structures

We are an industry leader in the design, inspection, and repair of heavy movable structures MORE >Services | Heavy Movable Structures -

Our knowledge of bridge performance is supported by technical expertise in structural... MORE >Services | Bridge Engineering

Our knowledge of bridge performance is supported by technical expertise in structural... MORE >Services | Bridge Engineering -

We work with owners, project architects and engineers, and contractors to execute successful... MORE >Services | Construction Observation and Troubleshooting

We work with owners, project architects and engineers, and contractors to execute successful... MORE >Services | Construction Observation and Troubleshooting