WJE PROJECTS

106th Street Bascule Bridge over the Calumet River

CLIENT |

Chicago Department of Transportation (CDOT) |

LOCATION |

Chicago, IL |

Rack and Pinion Gear, Machinery Frame, and Counterweight Repair Design

WJE was retained to investigate operational problems for the west leaf, which had resulted in interference between the northwest pinion gear and rack teeth. The project scope included inspection of the existing machinery and structural conditions; evaluation of mechanical alignment by precision survey; risk, cost, and service life assessments; design of mechanical drive train repairs; development of welding procedures; materials testing and petrography; design of structural foundation and counterweight repairs; oversight of construction; and bridge commissioning.

BACKGROUND

The 106th Street Bridge is a two-leaf trunnion bascule bridge designed by the Chicago Division of Bridges in 1927. This bridge uses a specially designed S-girder to support the inboard trunnions and operates often for vessels. Each bascule leaf consists of two built-up riveted steel trusses positioned 42 feet apart, with transverse floor beams supporting the roadway and sidewalk. In the open position, the bridge provides a clear opening of 220 feet over the Calumet River. The bridge operates approximately 8,000 times per year.

SOLUTION

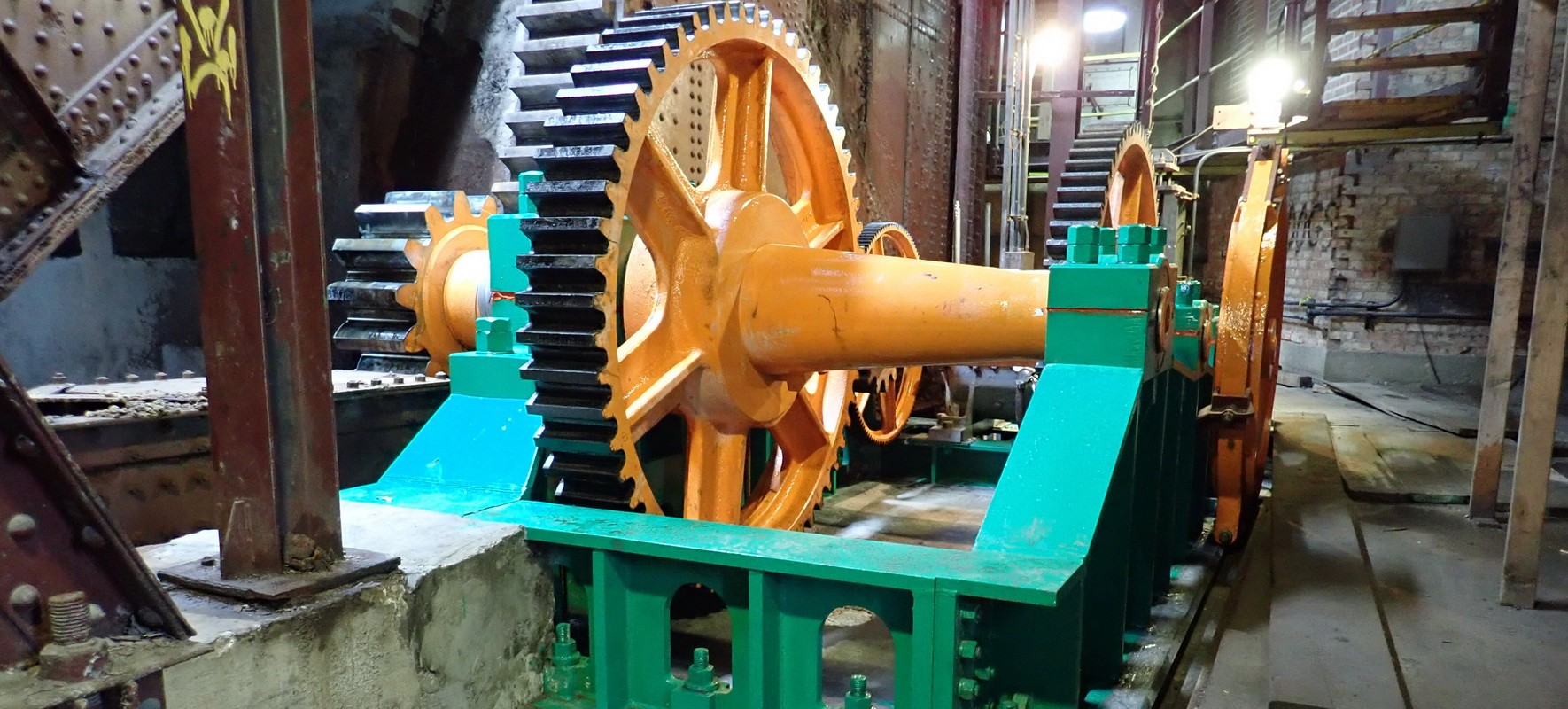

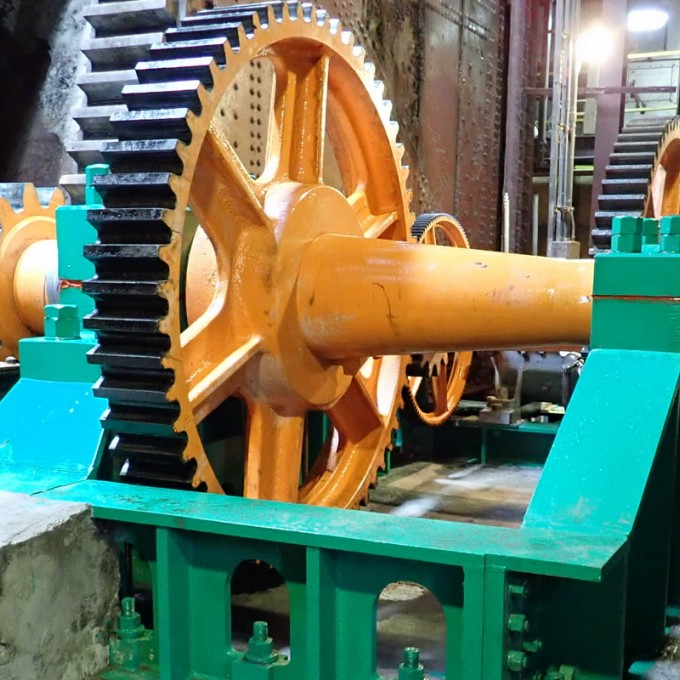

WJE identified significant misalignment of the northwest pinion drive shaft during the visual inspection and precision survey phase of the investigation. The existing location of the northwest machinery frame was found to be 1/2-inch forward of the ideal position. In addition, machinery frame distortion was identified along with severe rack tooth wear. Repair strategies were developed, and the “best value” option was selected by CDOT for implementation.

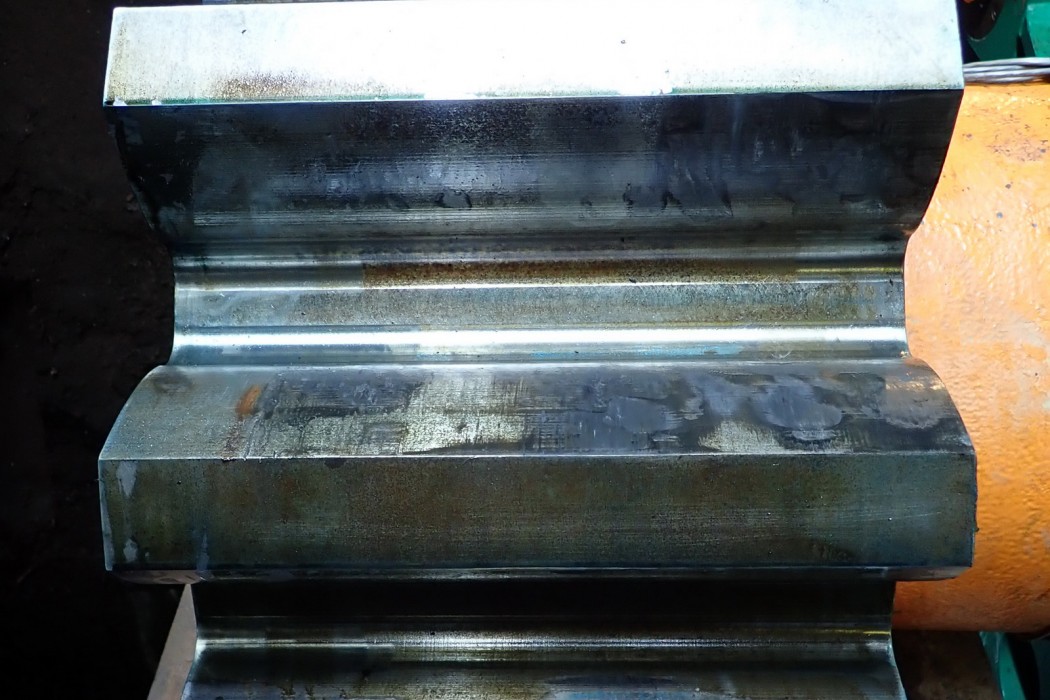

Structural and mechanical repair design was completed. Construction period services were then performed to assist the contractor in completion of rack tooth welded repairs to restore the existing teeth to their original profile, partial demolition and retrofit of existing machinery frame foundations, positioning of a new northwest machinery frame to provide optimal alignment/mesh with the repaired northwest rack teeth, and partial demolition and retrofit of existing leaf counterweight box.

WJE also provided mechanical design of a new pinion gear, shop inspection, and commissioning of the northwest drive train prior to shipment to the site for reinstallation, leaf balance testing by the dynamic strain gage method, and direction for final counterweight adjustments. Following all construction work, WJE directed the removal of temporary leaf shoring and the commissioning of the leaf to return it to normal service.