EXPERTISE // SERVICES // METALLURGY AND APPLIED MECHANICS

Metallurgical Consulting

Understanding the behavior of materials is challenging. Our metallurgical and welding consulting engineers have extensive experience in the characterization, selection, and performance of metals in a broad range of applications. Our aim is to be the consultant of choice by providing cost-effective solutions to your metal-related challenges. This is accomplished by drilling into the application on the technical level to derive the “bigger picture” of just how the product or component relates to an engineered system.

Our engineers have the tools, assets, and expertise necessary to address any technical challenges. Our goal is to provide optimized solutions—not just results—as part of a successful project.

Materials selections are based on an understanding of the application and identification of the service life needs. This may be a simple material upgrade or substitution, and depending on the complexity of the application, we can include a review of various material attributes such as strength, high-temperature properties, and corrosion resistance.

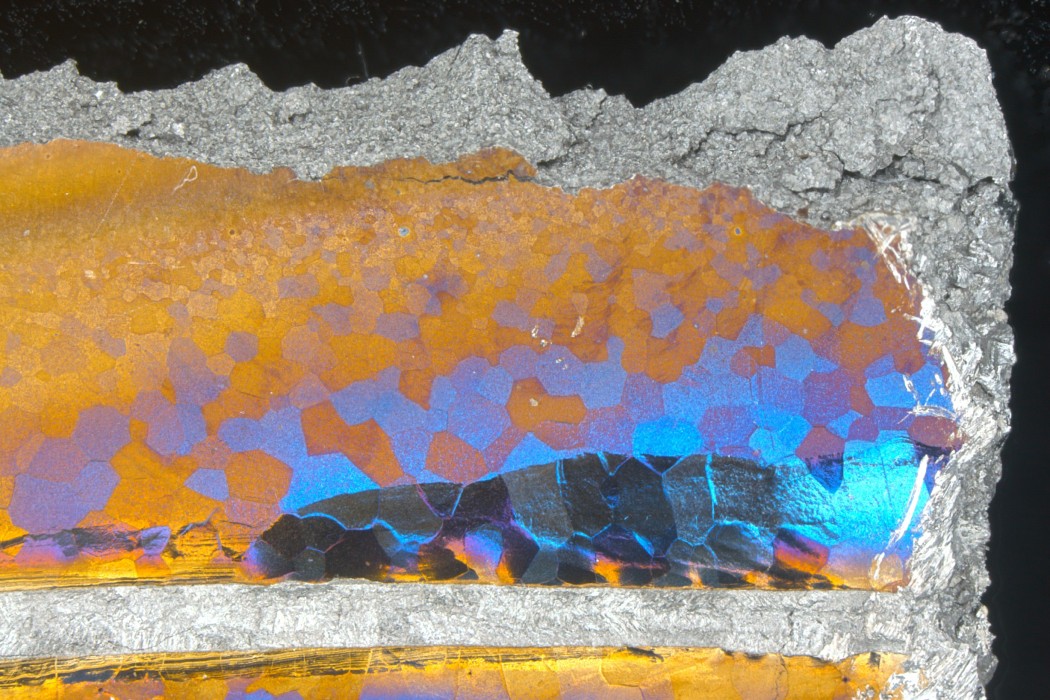

Material reviews are often conducted to properly address current or former failures. We routinely conduct extensive forensic investigations to identify the causes of component and system failures. Many times, these investigations start with a failure analysis to identify the root cause(s) of a specific component. This information then provides an understanding of component behavior and acts as a resource in the overall system review.

Gaining an understanding of how a certain component will perform or will degrade in each application is critical for reliable equipment performance. Our metallurgy and applied mechanics engineers offer confident points of view, alternatives, and pragmatic plans of attack to resolve your most challenging materials problems.

- Failure investigation and root cause analysis

- Laboratory and field testing of materials

- Forensic testing

- Weld engineering assessment

- Nonlinear finite element analysis

- Estimation of remaining service life

- Fatigue and fracture analysis

- Estimation of remaining strength and ductility

- Repair recommendations

- Component testing

- Materials attribute reviews and recommendations

- Materials selection

- High-temperature degradation/creep

- Corrosion assessment

- WJE CrackCalc™ (API 579 Fracture Mechanics Software)

RELATED INFORMATION

-

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics -

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy -

The JTC provides advanced testing and forensic capabilities to solve the most technically... MORE >Videos | Inside the Janney Technical Center

The JTC provides advanced testing and forensic capabilities to solve the most technically... MORE >Videos | Inside the Janney Technical Center -

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center