EXPERTISE // SERVICES // METALLURGY AND APPLIED MECHANICS

Metallography

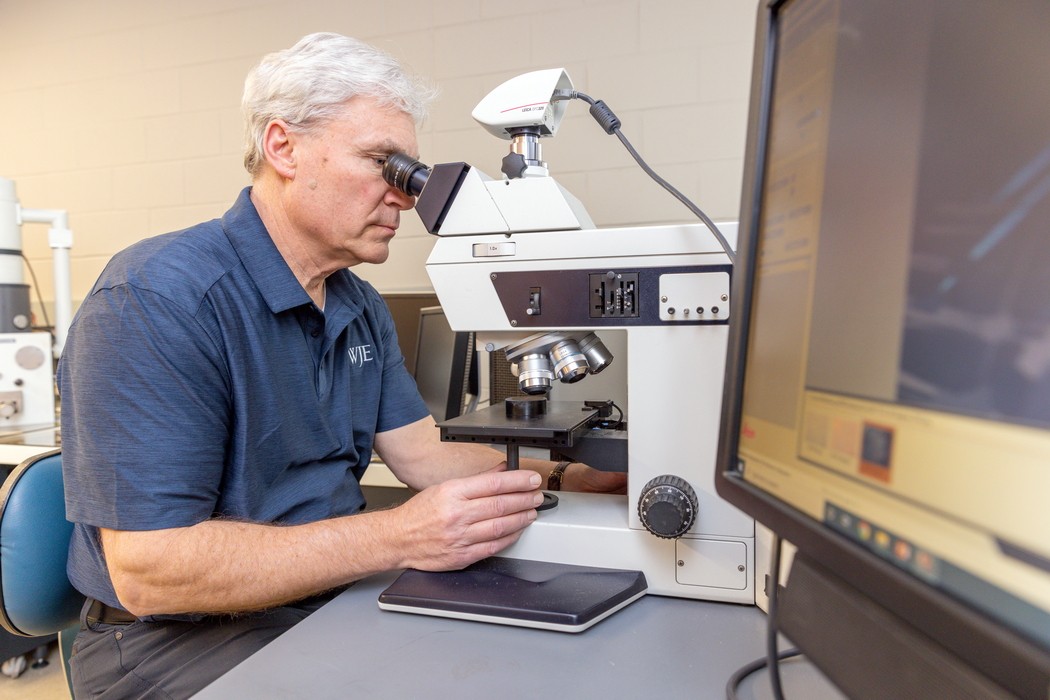

Metallography is the observation and examination of the microstructures of metals. The constituents of the microstructure consist of the grain structure, inclusions, or phases, and they are typically observed using incident light microscopy. The microstructure is revealed by using an etchant to selectively corrode certain phases or grain orientations of the alloy to reveal grain boundaries. Different chemical etchants are used for various base metals and different alloys. This reveals information about the size and shape of grains that can affect the macroscopic properties of a metal—such as tensile and elongation—as well as thermal, electrical, or corrosion properties.

Evaluations of microstructure for metal alloys generally consists of making a cross section through the location to be examined. The cross section is mounted in an epoxy resin or bakelite puck and polished to a mirrored finish that is free of damage and artifacts.

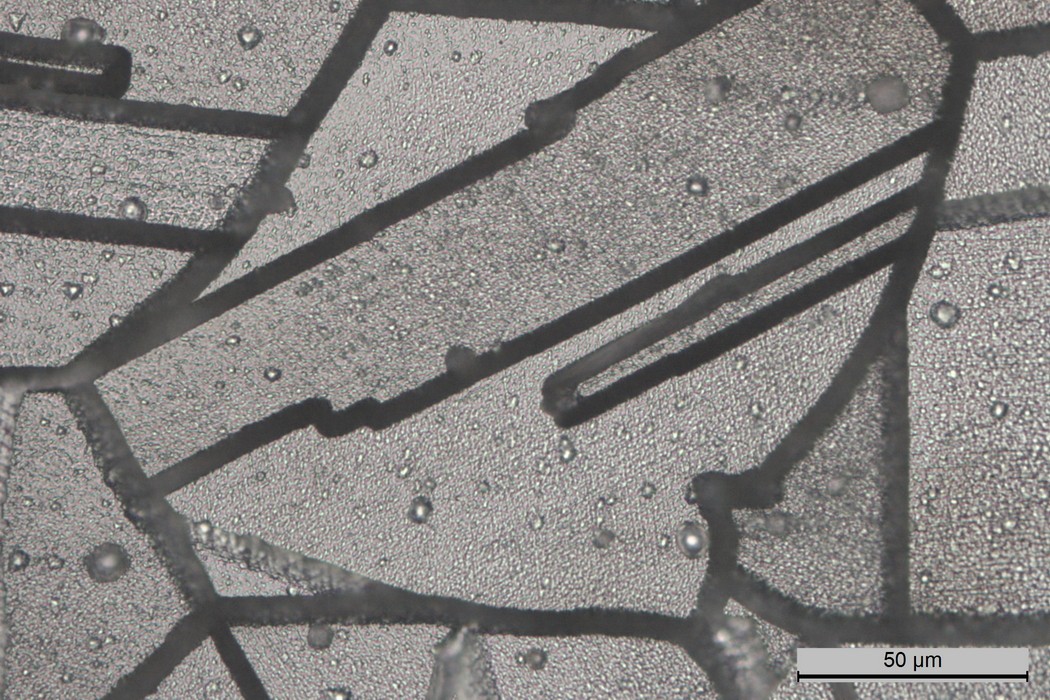

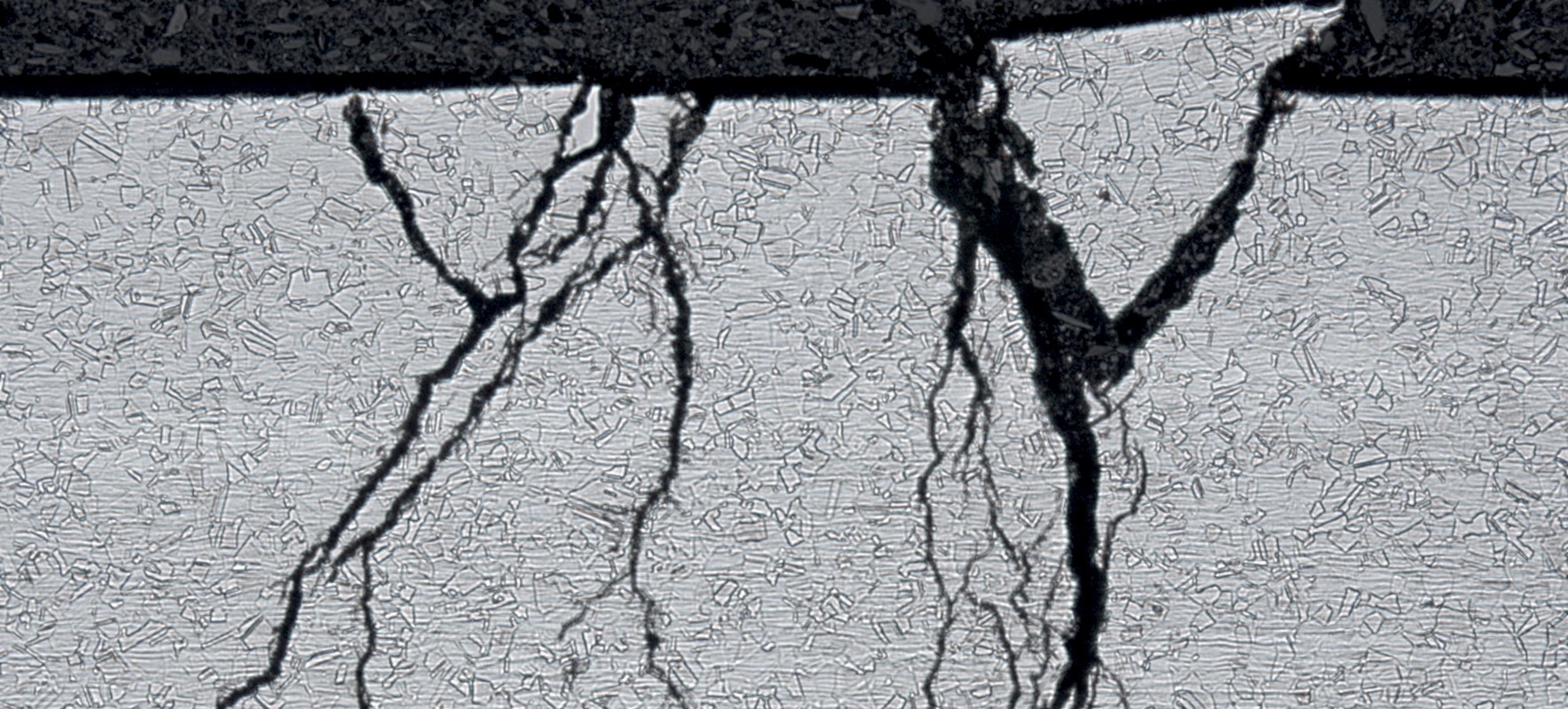

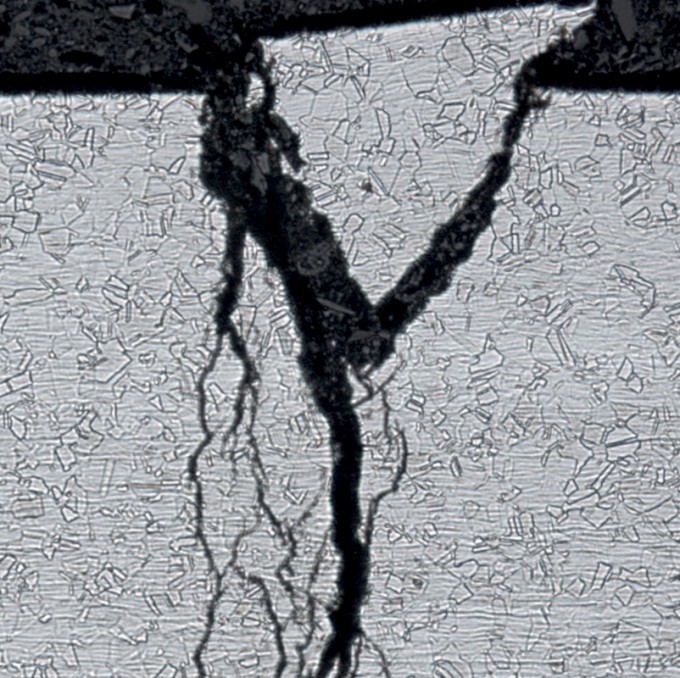

The inclusion content and some surface characteristics of an alloy can be observed in the unetched condition (as-polished). Inclusion content is particularly useful for weldability examinations where excessive elongated inclusions can cause steel to be susceptible to lamellar tearing. Surface corrosion, such as pitting or dezincification, and crack features, such as being branched or jagged, can also be characterized in the unetched condition.

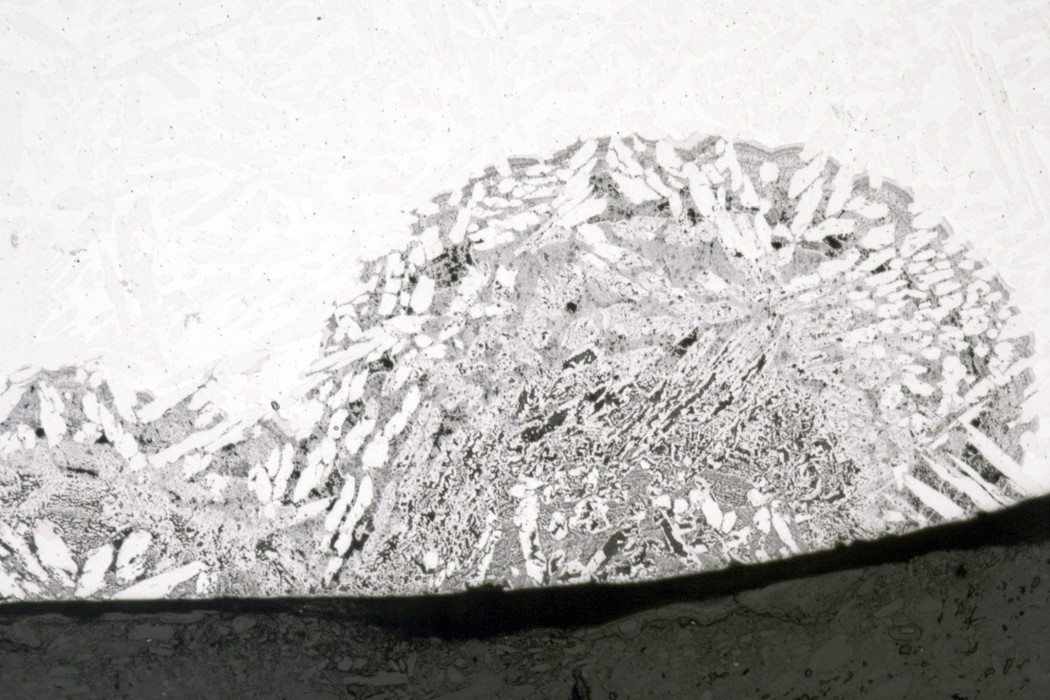

After etching the polished sample with the appropriate chemical or electrolytic etchant, information regarding the grain structure can be observed. Grain size and shape provides insight to potential mechanical properties of the metal such as strength, creep resistance, and fatigue. Intergranular versus transgranular cracking can also be characterized once the grain structure is revealed. In the cases of some stainless steels, etch tests can be used to determine if the material had been sensitized and prone to environmental corrosion.

- Metallographers routinely perform metallographic examinations on metal alloys such as carbon steels, cast irons, stainless steels, brasses, nickel alloys, and more

- Metallographic examinations can:

- Confirm conformance with a material specification

- Characterize heat treatments and surface conditions

- Determine detrimental phases hindering mechanical properties of the alloy

- Provide information in weldability assessments

- Assist in failure analysis examinations

RELATED INFORMATION

-

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics -

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center -

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy -

Insights that will help reduce outage uncertainty and enhance the reliability of your equipment. MORE >Webinars | Keeping the Lights On: Managing Large Power Generation Assets

Insights that will help reduce outage uncertainty and enhance the reliability of your equipment. MORE >Webinars | Keeping the Lights On: Managing Large Power Generation Assets