WJE PROJECTS

University Parking Garage

CLIENT |

Major University |

LOCATION |

New Haven, CT |

Structural Analysis and Steel Repairs

This parking garage had several chronic problems that could not be solved by several previous engineering firms engaged by the Owner throughout the life of the structure. The garage was leaning several inches. The columns’ webs were buckling where pinched by the girder moment connections, and long-term water infiltration and exposure to deicing salts caused severe corrosion of the steel frame. The Owner thought the garage needed to be torn down, but engaged WJE to determine a way to extend the life of the garage and maintain vital parking capacity.

BACKGROUND

This steel-framed garage was built into a hillside in 1974. It provides 700 parking spaces on five levels with a compact, double-helix flow of traffic through the garage. The structural system consists of steel girders with composite concrete slabs.

SOLUTION

WJE began with a comprehensive assessment of the garage, including section loss measurements and a multiyear plumbness survey. During probing, we discovered steel columns with nearly 100 percent section loss.

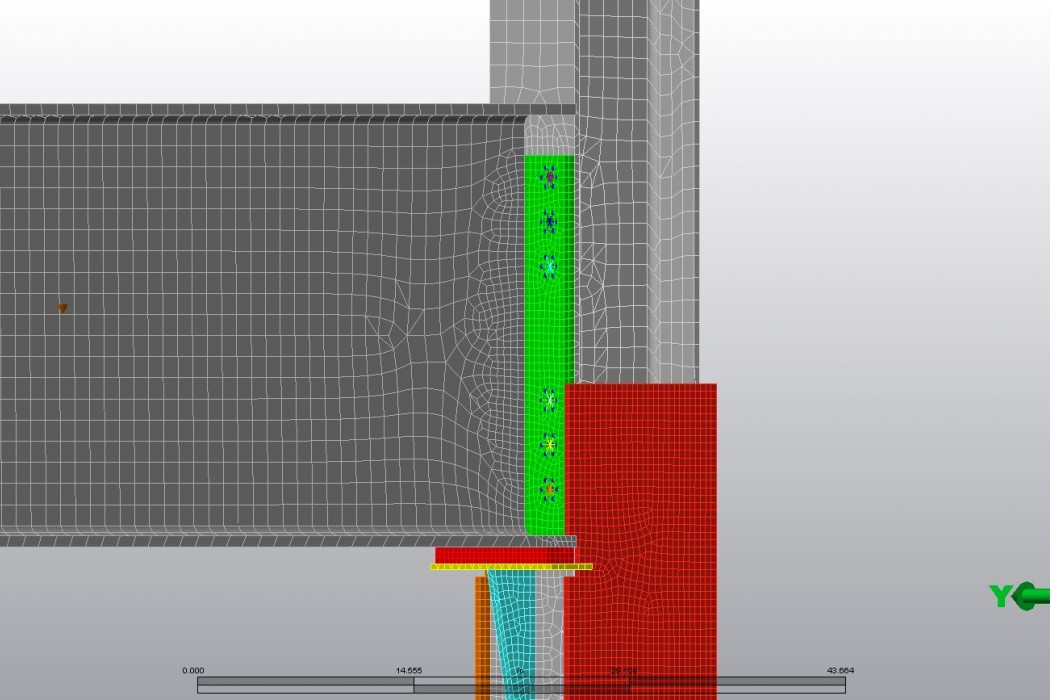

The structure was modeled in CSI SAP2000 and a detailed finite element analysis using Autodesk Simulation Mechanical. The finite element model of a typical moment connection served to locate points of high stress in the connection, particularly at the bolts and welds. In combination with the finite element model, the SAP model provided a better understanding of the behavior of the gravity system and the utilization ratios of the columns.

Columns with critical utilization ratios and severe section loss were selected to receive specialized repairs. Our repair design permitted direct transfer of concentrated girder flange forces without further pinching the columns. Our repair design also restored the cross-section of the heavily corroded columns. Braced frames were added to resist the lateral earth pressures imposed by the improperly designed retaining walls. Repairs were designed to minimize disruption to parking capacity. Our collaboration with the steel fabricator enabled just-in-time design and manufacturing of the shoring, as well as the permanent repairs to achieve the client’s goals.

RELATED INFORMATION

-

We apply the lessons learned from more than 175,000 projects to provide clients with a full... MORE >Services | Condition Evaluation

We apply the lessons learned from more than 175,000 projects to provide clients with a full... MORE >Services | Condition Evaluation -

Our professionals deliver practical repair and rehabilitation services that maximize the... MORE >Services | Repair and Rehabilitation

Our professionals deliver practical repair and rehabilitation services that maximize the... MORE >Services | Repair and Rehabilitation -

When the integrity or condition of a structure is in question, clients rely on us for answers MORE >Services | Structural Engineering

When the integrity or condition of a structure is in question, clients rely on us for answers MORE >Services | Structural Engineering -

Learn about our New Haven office MORE >Offices | New Haven

Learn about our New Haven office MORE >Offices | New Haven