WJE PROJECTS

St. Regis Chicago

CLIENT |

James McHugh Construction Co. |

LOCATION |

Chicago, IL |

Facade Access Equipment

OSHA 1910.66 requires that building owners provide assurance to users of the equipment that the equipment meets all relevant OSHA requirements. The assurance, or “certification” is required after initial installation of the equipment and must be based on field inspection and testing prior to its first use. OSHA does not provide specific requirements regarding the manner in which testing of facade access equipment is performed. Building owners seeking certification of their facade access equipment typically rely on engineers to provide the required certification.

BACKGROUND

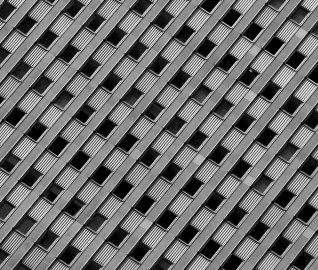

The St. Regis Chicago is a ninety-three-story, concrete-framed structure clad with an aluminum and glass curtain wall. Facade access equipment is located on Levels 10, 11, 47, 71, and 96 (main roof). This equipment is intended to be used for window washing and other maintenance activities on the building facade.

At Levels 47, 71, and 96, the facade access systems consist of building maintenance units (BMUs) that can traverse the perimeter of the roofs and suspend dedicated roof-rigged powered platforms. At Levels 10 and 11, a davit system is used to suspend a dedicated ground-rigged powered platform. Fall arrest anchorages are used for worker fall protection when erecting davits near roof edges.

SOLUTION

WJE performed the following services associated with the facade access systems at the St. Regis Chicago:

- Reviewed the relevant drawings by the BMU equipment manufacturer and performed an analysis to determine appropriate test loads based on design information provided in the drawings

- Developed testing protocols to verify that the facade access support systems have sufficient strength to resist the required loads

- Load tested the BMU tie-down components at Levels 47, 71, and 96

- Load tested both the davit bases and the fall arrest anchorages at Levels 10 and 11

- Prepared reports for each level, summarizing methods of facade access, results of the load tests, and requirements for equipment use and periodic inspections

All tested components successfully sustained the test loads without any significant permanent deformation or failure. Based on the test results, WJE was able to conclude that the components meet or exceed the minimum capacities required by OSHA and are suitable for compliant use subject to the limitations described in our reports.

RELATED INFORMATION

-

Our building science expertise and resources are the result of a commitment to understanding the... MORE >Services | Building Science

Our building science expertise and resources are the result of a commitment to understanding the... MORE >Services | Building Science -

When the integrity or condition of a structure is in question, clients rely on us for answers MORE >Services | Structural Engineering

When the integrity or condition of a structure is in question, clients rely on us for answers MORE >Services | Structural Engineering -

We apply the lessons learned from more than 175,000 projects to provide clients with a full... MORE >Services | Condition Evaluation

We apply the lessons learned from more than 175,000 projects to provide clients with a full... MORE >Services | Condition Evaluation -

We understand the myriad challenges faced by building owners and managers, and we're committed... MORE >Markets | Buildings

We understand the myriad challenges faced by building owners and managers, and we're committed... MORE >Markets | Buildings