WJE PROJECTS

Pin and Link Assembly Inspections

CLIENT |

North Dakota Department of Transportation (NDDOT) |

LOCATION |

Various Locations, ND |

Visual and PAUT Inspection of Bridge Pin and Link Assemblies

WJE was retained by NDDOT to perform a visual inspection and phased array ultrasonic testing (PAUT) on the pinned connections of seventeen bridges across the state—a total of 344 bridge pins in pinned hinge or pin and hanger connections. Components in the vicinity of the pin connections were examined visually at arm’s length, and connecting pins were subjected to ultrasonic testing using axially oriented scans. WJE team used ultrasonic scans to inspect the connecting pins, while arm’s- length examinations were used for evaluation of components in the vicinity of the pin connections.

BACKGROUND

Each of the bridges has twelve to thirty-six pins with pin lengths from 5.2 to 10.3 inches and pin diameters from three to five inches. Twelve of the bridges cross rivers and five cross over railroads. Nine bridges are three-span structures with two cantilever or anchor spans and one suspended span supported by pin and hanger or pinned hinge connections. The other eight bridges vary in configuration with between five to eight spans and two to six pin and link connections per girder line. Eleven of the bridges include four girder lines, two bridges include five girder lines, three bridges include six girder lines, and one bridge includes seven girder lines.

SOLUTION

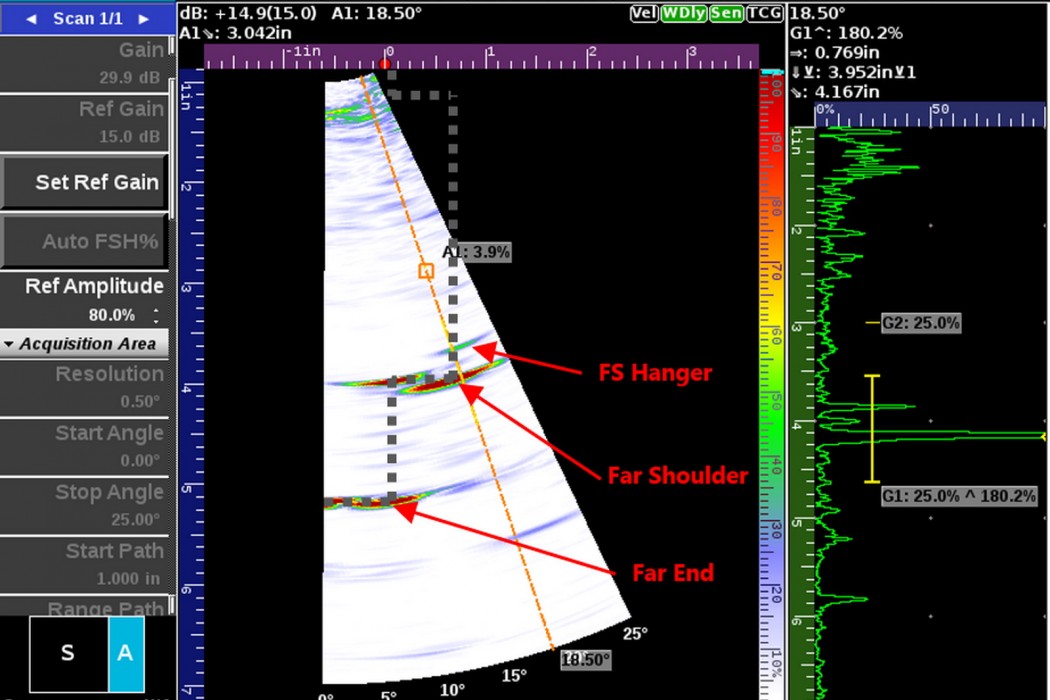

The WJE team, including an engineer who specializes in PAUT and an ANST Level III Ultrasonic Testing Inspector, accessed the pinned connections via a truck-mounted under-bridge inspection apparatus. Testing included PAUT scans using an angular range of 0°–25° from both ends of the pin. Lower scanning angles (approximately 0°–5°) were used to measure the total pin length and distance to the far shoulder, which was recorded for each pin end tested. The ultrasonic response from these geometric features demonstrated the axial continuity of each pin. The higher scanning angles (approximately 10°–25°) were used to assess the overall condition of the pin barrel surface.

WJE developed reports for each bridge in accordance with NDDOT requirements and included an evaluation of the condition of the pinned connections, recommended actions, summary of the pins’ dimensions, comments about each pin, and photos of relevant findings. The summary report also provided screenshots from the test instrument displays for each pin.