WJE PROJECTS

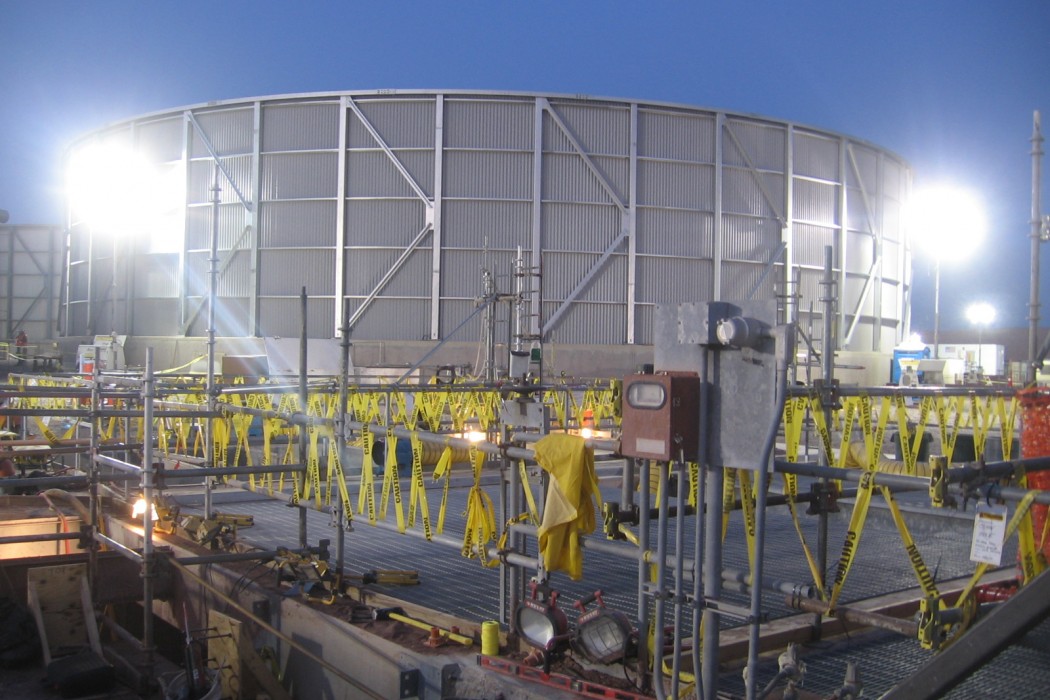

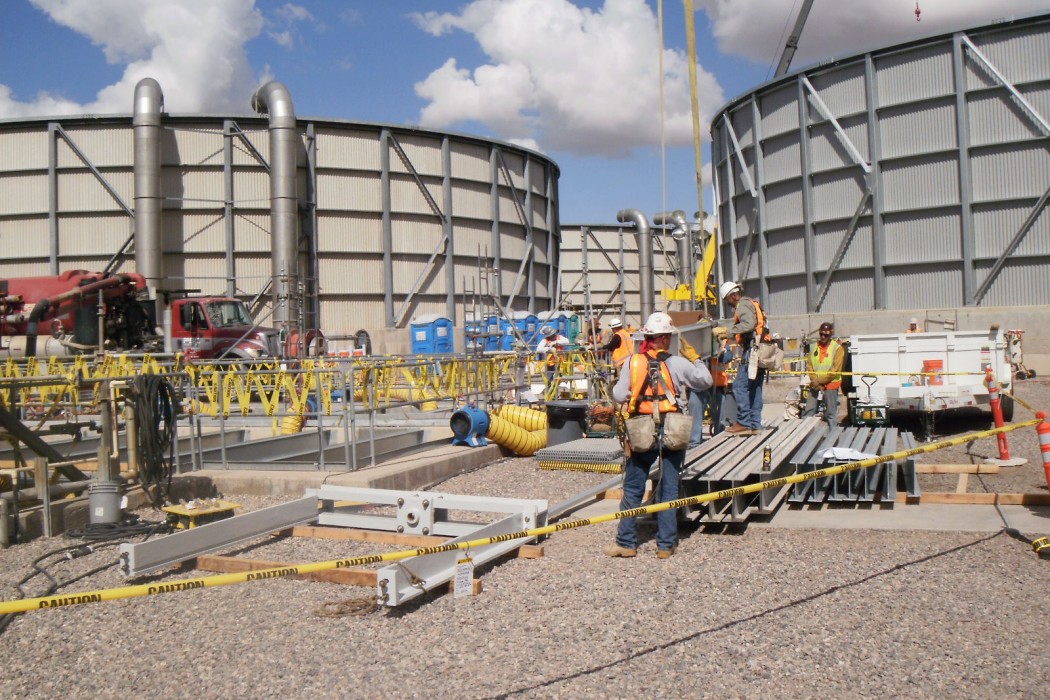

Palo Verde Nuclear Generating Station Water Reclamation Facility

CLIENT |

Arizona Public Service |

LOCATION |

Tonopah, AZ |

Water Reclamation Facility Condition Assessment and Repair Design

After Palo Verde personnel observed various distress conditions at the Water Reclamation Facility (WRF), the client retained WJE to perform a limited condition assessment and to develop a comprehensive maintenance and repair plan. During a regularly scheduled shutdown, the WRF gave WJE seven days to perform the visual and materials assessment, which WJE completed by working two twelve-hour shifts each day.

BACKGROUND

The Palo Verde Nuclear Generating Station is a nuclear power plant located about forty-five miles west of Phoenix. It is currently the largest nuclear generating facility in the United States. Palo Verde is also the only nuclear generating facility in the world that is not located adjacent to a large body of aboveground water. Instead, it uses water from the Palo Verde WRF.

SOLUTION

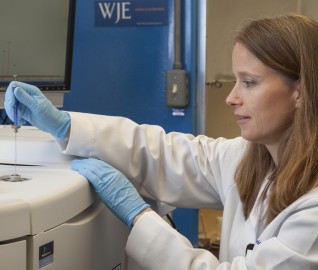

WJE performed a visual survey, cover depths, copper-copper sulfate half-cell potential testing, corrosion rate assessments at all half-cell test locations that indicated the presence of active corrosion, and carbonation testing. Laboratory evaluations of core samples, which were necessary to assess the general quality and integrity of the concrete in the various structural elements, included rapid chloride ion permeability and petrographic analyses. In addition, WJE materials scientists evaluated the level of chloride concentrations at various depths relative to the exposed concrete surface to predict the onset of chloride-induced corrosion of the reinforcement and to determine the remaining service life of the element. WJE concluded that the primary distress mechanism was due to corrosion of the embedded reinforcement and structural members as well as ongoing alkali-silica reactivity in some concrete elements. WJE recommended a comprehensive approach that could be instituted at localized areas of the plant or for many of the concrete structures. The team proposed four repair options to provide the structures an additional twenty-five-year service life: installation of an impressed current cathodic protection system, use of passive anodic protection system, installation of a coating system coupled with bulk anodes, or installation of a concrete lining system containing sacrificial anodes.

RELATED INFORMATION

-

Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing

Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing -

We have pioneered the use of nondestructive evaluation methods—such as ground penetrating... MORE >Services | Nondestructive Evaluation

We have pioneered the use of nondestructive evaluation methods—such as ground penetrating... MORE >Services | Nondestructive Evaluation -

Our professionals deliver practical repair and rehabilitation services that maximize the... MORE >Services | Repair and Rehabilitation

Our professionals deliver practical repair and rehabilitation services that maximize the... MORE >Services | Repair and Rehabilitation