WJE PROJECTS

Cross-Linked PEX Plumbing Pipes

CLIENT |

Law firm representing homeowner's insurance company |

LOCATION |

Undisclosed, AL |

Evaluation and Materials Testing of Oxidative Failure

WJE conducted laboratory investigations to determine the cause of leaks reported in PEX potable water-carrying pipes. Our studies confirmed that the observed cracks were the result of oxidative degradation of the PEX material, which directly led to the leaks. This oxidative degradation was caused by the depletion of antioxidants, leading to a severe reduction in the pipes’ oxidative resistance by more than 90%.

BACKGROUND

Cross-linked high density polyethylene (PEX) pipes, commonly used for carrying potable water, typically formulated with antioxidants to enhance in-service durability. However, components found in potable water, particularly those used as disinfectants, can cause oxidation of the PEX material, which may potentially lead to pipe failure.

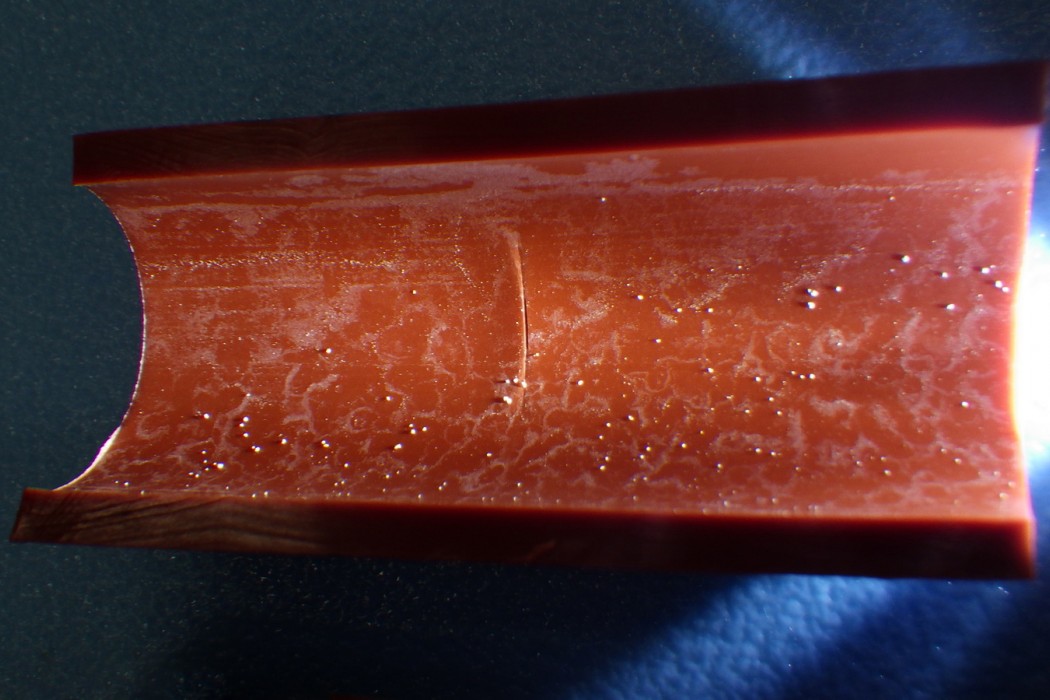

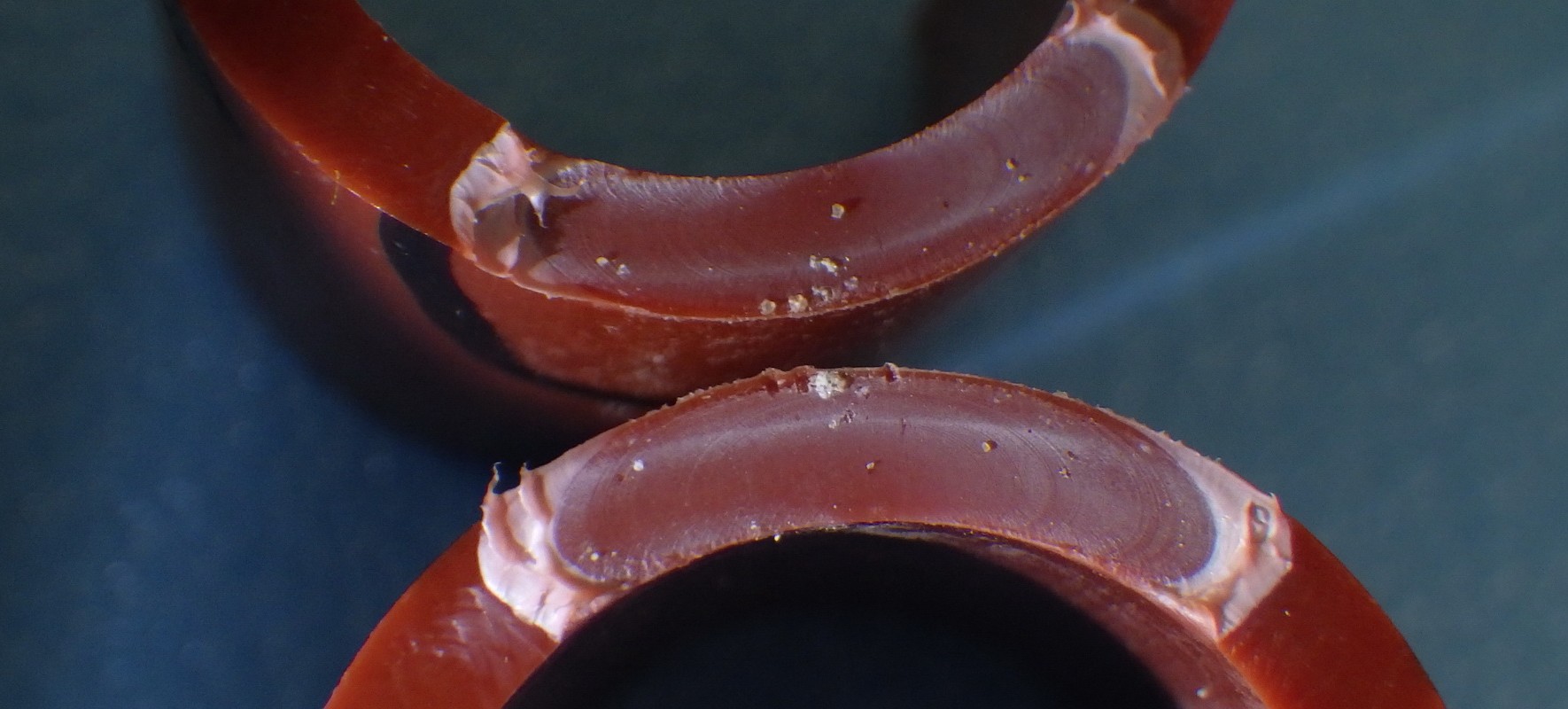

The failed pipes in question exhibited through-thickness perforations, which were consistent with the observed leaks in the system.

SOLUTION

The following techniques were used in the investigation of the causes of pipes failure:

- Microscopical examination revealed that through-thickness cracks initiated on the interior wall of the pipes, which indicated that the failure was not due to external damage during installation or handling.

- FTIR spectroscopy detected oxidation of the PEX material, particularly concentrated on the inner wall of the pipes.

- Oxidative Induction Time (OIT) testing, conducted via differential scanning calorimetry (DSC), demonstrated very low antioxidant concentrations in the PEX materials, resulting in minimal oxidative resistance.

- Chemical imaging using the micro-ATR FTIR technique enabled the visualization of oxidation progression, mapping it from the crack origin through the pipe’s thickness. This method employed a chemical marker identified by FTIR spectroscopy, reinforcing the findings from both microscopical examination and OIT testing.

- Degree of crystallinity (DOC) analysis by DSC, which assesses the PEX material’s resistance to thermal oxidation, revealed changes in the DOC of the inner pipe wall, attributed to oxidative degradation.

- Compositional analysis by TGA detected the presence of contaminants on the interior surface of the most severely damaged pipes. These contaminants likely altered physical properties as thermal resistance and mechanical strength, contributing to the pipe failure.

RELATED INFORMATION

-

Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing

Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing -

WJE has been at the forefront of new construction technology testing and research for more than... MORE >Markets | Testing and Research

WJE has been at the forefront of new construction technology testing and research for more than... MORE >Markets | Testing and Research -

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center -

Learn about our Northbrook office MORE >Offices | Northbrook

Learn about our Northbrook office MORE >Offices | Northbrook