WJE PROJECTS

92nd Street Bascule Bridge West Leaf

CLIENT |

City of Chicago Department of Transportation (CDOT) |

LOCATION |

Chicago, IL |

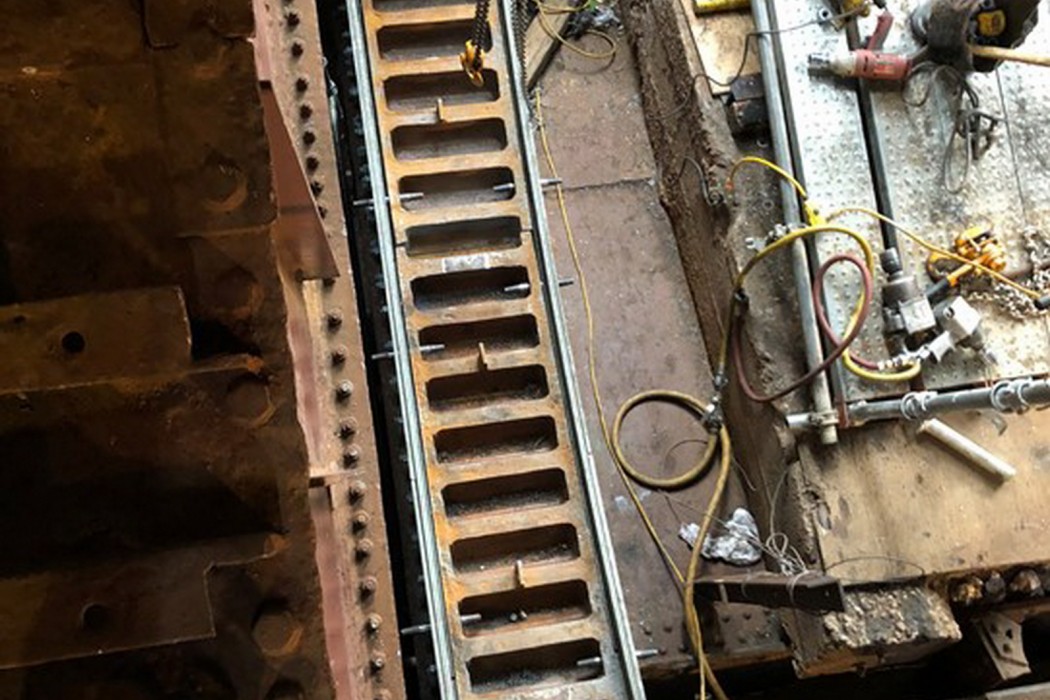

Rack and Pinion Repair

Operational problems at the mesh of the rack and pinion for both trusses of the west leaf led to two major repair projects. The objective of each repair project was to reestablish proper meshing of the rack and pinion gear teeth while maintaining the existing pinion and shaft alignment. CDOT engaged WJE to provide a structural and mechanical review of the operational difficulties and provide recommendations.

BACKGROUND

The double-leaf, trunnion-type Bascule Bridge carries one lane of traffic in each direction across the Calumet River. Each bascule leaf is comprised of two built-up riveted steel trusses that support a floor system and bridge deck. Bridge operation is facilitated by a rack and pinion drive system, with circumferential rack segments installed within each truss.

The west leaf was struck by vessels on several occasions, resulting in a reported misalignment between the southwest rack and pinion gear drive machinery. In order to operate the bascule leaf, the shaft attached to the southwest pinion gear was temporarily disengaged. The west leaf was subsequently driven only by the northwest rack and pinion.

SOLUTION

A precision survey and other field measurements were performed prior to each repair project to determine the position of the bridge trunnions, racks, pinions, and pinion shafts. A mechanical review was carried out to evaluate various options to address the machinery misalignments and to improve the functionality of both rack and pinion systems on the west leaf. The team provided drawings and specifications for both projects.

Seeking a temporary repair during the first project, CDOT elected to remove and refurbish the existing rack segments and reinstall them using the existing alignment with new special pinions. Following approximately five years of normal operation, wear of the new south pinion teeth began to cause operational issues. After conducting new field measurements and a precision survey, the project team recommended options to further improve the mesh of the north and south rack and pinion systems. For the second project, the final design required both existing pinions to be modified to restore the original gear tooth profile. All rack segments were removed and repositioned to restore an optimal radial alignment. A new system of structural rack side plates was installed to facilitate the realignment work. Other structural and mechanical engineering design and component installation challenges were overcome, and the bridge was successfully returned to service.

RELATED INFORMATION

-

We are an industry leader in the design, inspection, and repair of heavy movable structures MORE >Services | Heavy Movable Structures

We are an industry leader in the design, inspection, and repair of heavy movable structures MORE >Services | Heavy Movable Structures -

Our knowledge of bridge performance is supported by technical expertise in structural... MORE >Services | Bridge Engineering

Our knowledge of bridge performance is supported by technical expertise in structural... MORE >Services | Bridge Engineering -

We engage a full suite of state-of-the-art instrumentation and monitoring capabilities to test... MORE >Services | Instrumentation and Monitoring

We engage a full suite of state-of-the-art instrumentation and monitoring capabilities to test... MORE >Services | Instrumentation and Monitoring -

We collaborate with all project stakeholders throughout the design process to ensure the proper... MORE >Services | Systems and Components

We collaborate with all project stakeholders throughout the design process to ensure the proper... MORE >Services | Systems and Components