EXPERTISE // SERVICES // MATERIALS EVALUATION AND TESTING

Corrosion Assessment and Service Life Evaluation (WJE CASLE™)

We are a leader in durability assessment services for reinforced concrete structures. To support our practice, we have developed WJE CASLE™ service life modeling software to predict the development of corrosion-related damage in concrete structures. These predictions help our engineers more effectively evaluate remaining service life and guide repair decisions for existing structures, and develop durability plans and protection strategies for new structures. Developed in-house, WJE CASLE™ offers full control of the evaluation process and facilitates a customizable approach to the circumstances and exposure conditions unique to each project.

APPLICATION

WJE CASLE™ has been used to perform service life modeling for both existing and new construction, including transportation, power generation, industrial, and governmental structures.

A major advantage of the software is that it considers site-specific conditions, including construction geometry, materials behavior, sealers, coatings, corrosion-resistant reinforcing, the presence and installation of overlays, pre-existing chloride profiles, concrete cracking, and two-sided exposure conditions, singularly or in combination.

In contrast to open-source modeling programs, WJE CASLE™ was developed to be flexible and customizable to provide durability assessment solutions. We frequently add to or improve on the capability of the software in response to project-specific needs.

METHODOLOGY

The effectiveness of WJE CASLE™ is rooted in two main concepts: 1) the inputs are derived from condition assessment findings measured directly from an existing structure or design parameters and exposure conditions specific to a new structure, and 2) predictions of future performance must consider the variability of key corrosion-controlling parameters in a given element. WJE CASLE™ accounts for these items by using probabilistic-based modeling.

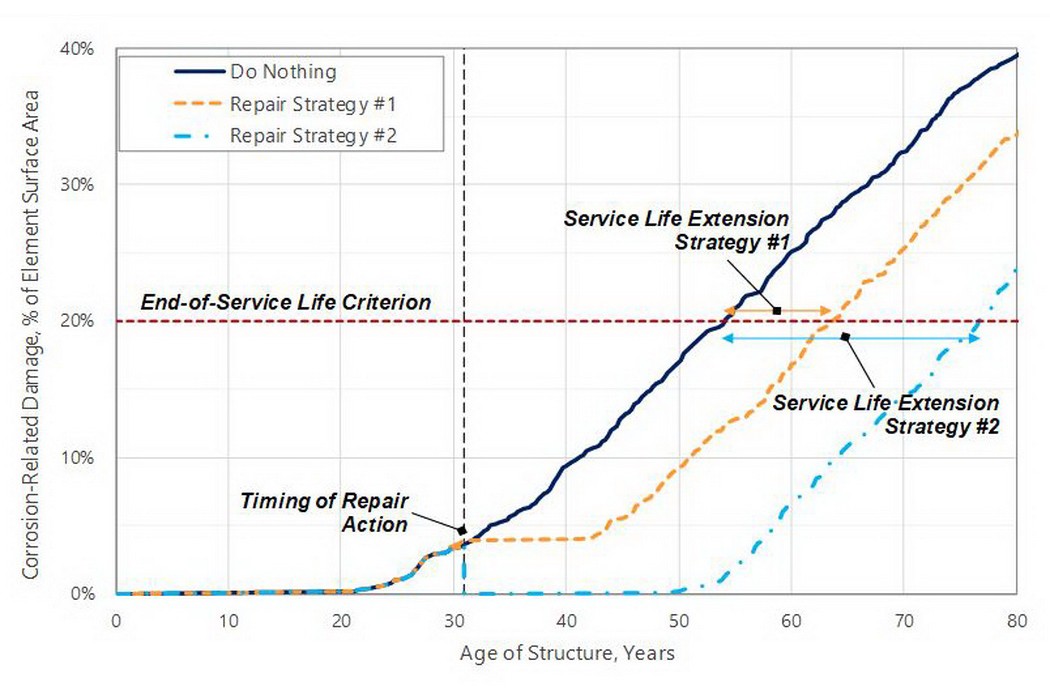

In the case of existing structures, this approach is used to predict the amount of concrete surface area or percentage of elements affected by corrosion-related damage. This recognizes that corrosion is a local process that can develop at multiple locations on a structure with time. The predicted damage is compared to the project-defined service life requirement.

In new structures, the probability of damage with time is predicted based on statistical distributions describing the potential variation of key corrosion-influencing parameters within the as-constructed structure.

Conceptualizing the Corrosion Process

Corrosion-related damage to concrete can be conceptualized in two stages: 1) initiation time (ti), the time elapsed prior to the start of the corrosion reaction; and 2) propagation time (tp), the time elapsed from when corrosion begins and to when build-up of corrosion product is sufficient to cause damage to the concrete. For chloride-induced corrosion, the initiation time is modeled based on the chloride exposure, the resistance of the concrete to chloride ingress (including the effect of cracks), and the concrete cover over the embedded steel reinforcement. A finite difference solution-based representation of Fickian diffusion is used to calculate the evolution of chloride concentration with depth over time. For carbonation-related corrosion, the initiation time is modeled based on the resistance of the concrete to the carbonation process and the concrete cover over the bars. For both corrosion mechanisms, the time of corrosion propagation is related to the corrosion rate.

Advantages of the WJE CASLE™ Modeling Approach

Our approach is founded on the idea that the best prediction of an existing structure’s future performance is generated by careful evaluation of its past performance and its actual, current condition. Our durability assessment methods are based on in-situ performance of the concrete and steel within the structure. The probabilistic approach accounts for the inherent variation in reinforced concrete construction, exposure, and deterioration. Unlike deterministic approaches that assume corrosion progresses similarly throughout the modeled structure, the probabilistic approach recognizes that damage is likely to occur in those areas where overlapping conditions conducive to corrosion occur (e.g., harsh exposure and low cover). This approach has been validated through comparison to observed field conditions in numerous existing structures, including bridges, port facilities, coastal structures, and power plants. Furthermore, because we perform the field investigation, material analysis, and service life modeling in-house, the project objectives remain at the forefront, allowing results to be expedited efficiently.

For new structures, we utilize a customizable approach to consider the circumstances and exposure conditions unique to the modeled structure to guide the development of comprehensive durability plans. WJE CASLE™ relies on our extensive experience inspecting, testing, and analyzing existing structures and is regularly refined to reflect our ever-expanding understanding of factors affecting durability.

RELATED INFORMATION

-

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center -

Owners and contractors rely on our specialized construction knowledge to properly detail and... MORE >Services | Construction Engineering

Owners and contractors rely on our specialized construction knowledge to properly detail and... MORE >Services | Construction Engineering -

Our professionals deliver practical repair and rehabilitation services that maximize the... MORE >Services | Repair and Rehabilitation

Our professionals deliver practical repair and rehabilitation services that maximize the... MORE >Services | Repair and Rehabilitation -

When the integrity or condition of a structure is in question, clients rely on us for answers MORE >Services | Structural Engineering

When the integrity or condition of a structure is in question, clients rely on us for answers MORE >Services | Structural Engineering