In a sandwich panel, core-to-facing bond integrity is necessary to maintain facing stability and permit load transfer between the facings and core. This test method can be used to provide information on the strength and quality of core-to-facing bonds. It can also be used to produce flatwise tensile strength data for the core material. While it is primarily used as a quality control test for bonded sandwich panels, it can also be used to produce flatwise tensile strength data for structural design properties, material specifications, and research and development applications. Factors that influence the flatwise tensile strength and shall therefore be reported include the following: facing material, core material, adhesive material, methods of material fabrication, facing stacking sequence and overall thickness, core geometry (cell size, cell wall thickness), core density, adhesive thickness, specimen geometry, specimen preparation, specimen conditioning, environment of testing, specimen alignment, loading procedure, speed of testing, facing void content, adhesive void content, and facing volume percent reinforcement. Properties that may be derived from this test method include flatwise tensile strength. This test method determines the flatwise tensile strength of the core, the core-to-facing bond, or the facing of an assembled sandwich panel. Permissible core material forms include those with continuous bonding surfaces (such as balsa wood and foams) as well as those with discontinuous bonding surfaces (such as honeycomb).

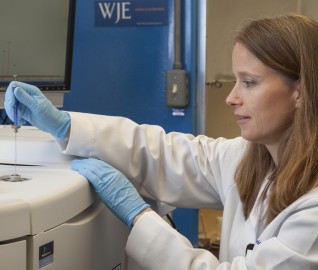

WJE laboratories are accredited by ANAB (ISO/IEC 17025) to perform testing standard ASTM C297 for Flatwise Tensile Strength of Sandwich Constructions.

Contact us to learn more.

Keywords

ASTM C297 - Flatwise Tensile Strength - Sandwich Construction

ICS CODE

83.120 (Reinforced plastics)

CITATION FORMAT

ASTM C297 / C297M-16, Standard Test Method for Flatwise Tensile Strength of Sandwich Constructions, ASTM International, West Conshohocken, PA, 2016,

www.astm.org

John E. Pearson, Principal and Laboratory ManagerWJE Northbrook MORE >People | John E. Pearson, Principal and Laboratory Manager

John E. Pearson, Principal and Laboratory ManagerWJE Northbrook MORE >People | John E. Pearson, Principal and Laboratory Manager WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center

WJE's Janney Technical Center (JTC) provides advanced testing and forensic capabilities to... MORE >Labs | Janney Technical Center Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing

Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing WJE was founded on a spirit of innovation—that everything can be improved and that... MORE >Services | Product Development, Evaluation, and Testing

WJE was founded on a spirit of innovation—that everything can be improved and that... MORE >Services | Product Development, Evaluation, and Testing