WJE PROJECTS

Arab Potash Company, Carnallite Structure

CLIENT |

Arab Potash Company |

LOCATION |

Ghor El Safi, Jordan |

Replacement of Deteriorated Concrete Slab

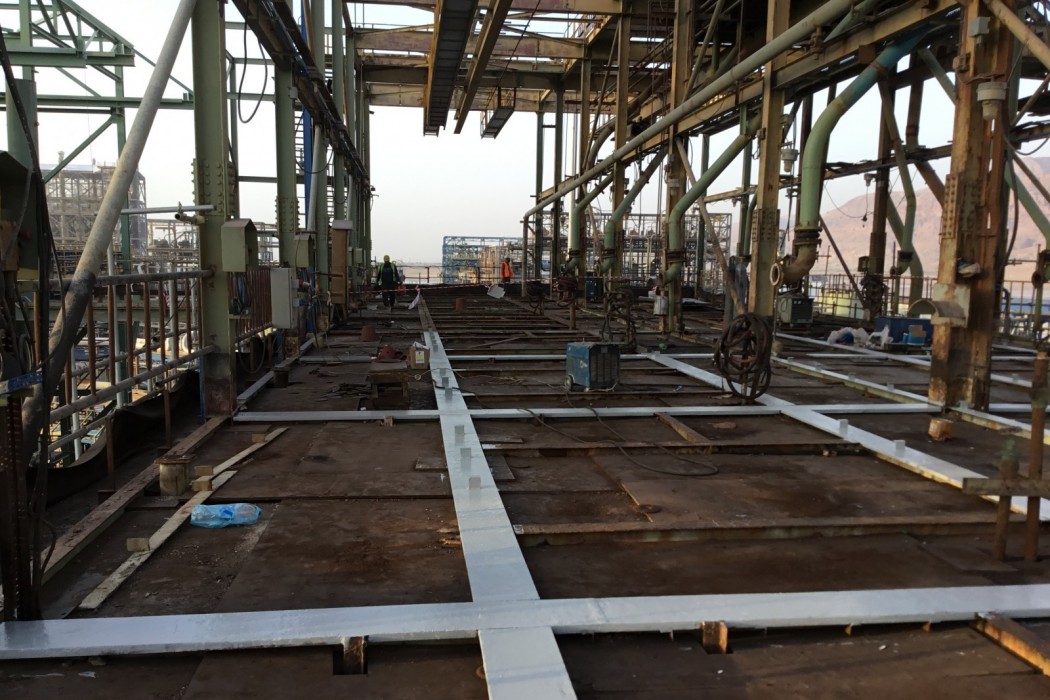

Long-term exposure to hot leach product (HLP) led to advanced deterioration of the concrete slab and supporting steel framing as well as deterioration of the concrete surface paste and corrosion of the embedded reinforcing steel. The supporting steel beams, columns, and bracing members exhibited advanced localized corrosion where the HLP product was allowed to pond. WJE was tasked with designing a replacement concrete slab capable of resisting the deleterious effects of the HLP while being able to support the dynamic loads from the centrifuge machines.

BACKGROUND

The Carnallite Structure is a 25-meter, five-story-high, open steel-framed structure constructed in the 1980s. An elevated concrete slab cast composite with the steel framing supports several centrifuge machines, which serve as an integral part of the hot leach production line at this potash plant. The equipment, which runs continuously, induces vibration into the supporting slab and sprays hot leach product, which is highly deleterious to both concrete and steel, directly onto the slab.

SOLUTION

WJE conducted a field investigation of the steel framing and concrete slab to determine the configuration and condition of the slab as well as the nature of the operational exposure. During the investigation, WJE measured the response of the slab during operation of the centrifuge machines to estimate the vibration levels in the slab.

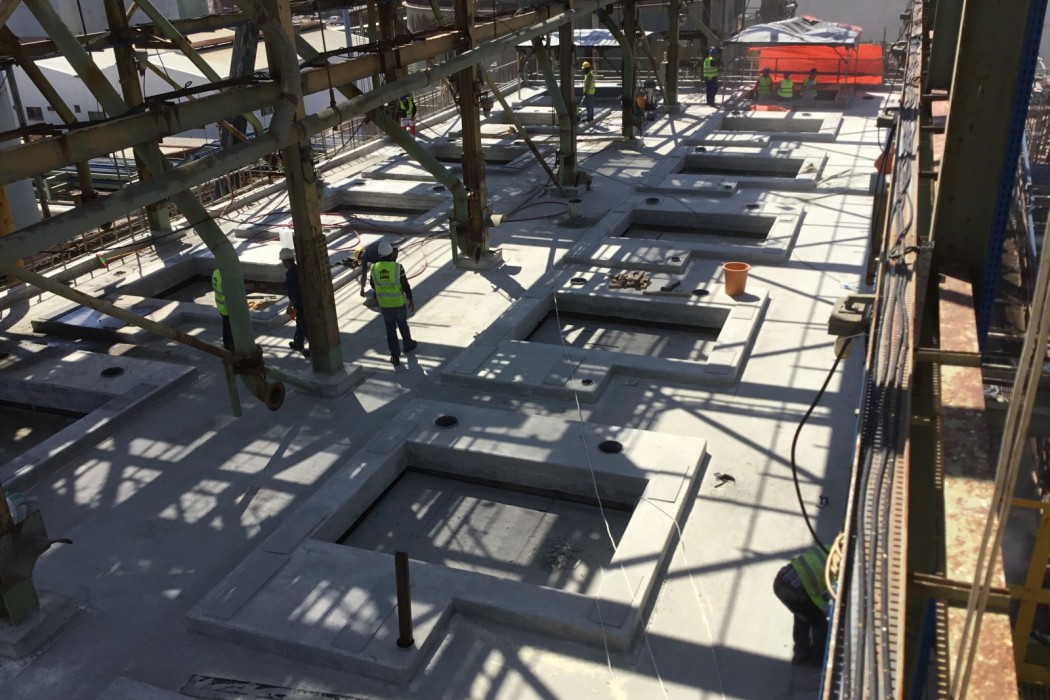

The new slab was reinforced with only glass fiber-reinforced polymer (GFRP) reinforcing bars. Although GFRP bars have been used in the past in structures exposed to chlorides, they had never been used in this application. Unlike steel bars, the GFRP bars exhibit nonductile fracture failures and are sensitive to low levels of sustained and cyclic loading. As such, WJE's design included an evaluation of these effects, including estimates of dynamic/cyclic loads from the operation of the centrifuge machines. The slab concrete was designed to be relatively impermeable, and included considerations for locally available materials. To prevent deterioration of the concrete surface paste, the slab design included topping with a resinous protective system. Exposed steel elements were cleaned and coated with a three-coat high-performance marine paint.

WJE was on-site during construction to review installation of the GFRP rebar, specify steel repairs, and resolve other construction issues. The vibrational performance of the slab and GFRP bars were verified by dynamic sensors that had been embedded in the slab.

RELATED INFORMATION

-

We work with owners, project architects and engineers, and contractors to execute successful... MORE >Services | Construction Observation and Troubleshooting

We work with owners, project architects and engineers, and contractors to execute successful... MORE >Services | Construction Observation and Troubleshooting -

Our design professionals assist in making the overall project design achievable, maintainable,... MORE >Services | Design-Build

Our design professionals assist in making the overall project design achievable, maintainable,... MORE >Services | Design-Build -

Our professionals deliver practical repair and rehabilitation services that maximize the... MORE >Services | Repair and Rehabilitation

Our professionals deliver practical repair and rehabilitation services that maximize the... MORE >Services | Repair and Rehabilitation