WJE PROJECTS

Amine Splitter Tower

CLIENT |

Confidential |

LOCATION |

Texas Gulf Coast |

API 579-1 Fitness for Service Assessment of Crack-Like Indications

WJE was asked to perform a fitness for service assessment (FFS) to evaluate crack-like indications found at the shell longitudinal seams. During a planned outage, liquid penetrant testing identified several linear indications characterized as weld undercut defects. The objective of the effort was to evaluate the in-service damage and determine if the tower was safe to continue operating or if repairs were required prior to returning the vessel to service.

BACKGROUND

The Amine Splitter Tower is a type of distillation column that is used to separate components in a chemical plant. The tower was constructed as an unfired pressure vessel according to the ASME Boiler and Pressure Vessel Code in 1969. The 2-foot-6-inch Inner Diameter (ID) by 39-foot-6-inch seam/seam long tower was fabricated from grade 316 stainless steel, with a nominal shell thickness of 1/4 inch near the bottom and 3/16 inch in the upper section. The design uses rolled and butt welded shell courses with periodic tray support attachments.

SOLUTION

WJE performed a FFS evaluation based on API 579-1/ASME FFS-1 to determine whether the Amine Splitter Tower was safe to continue operating using Part 9, Assessment of Crack-Like Flaws. The assessment used a Level 2 methodology to establish limiting flaw or crack sizes under applicable design loading.

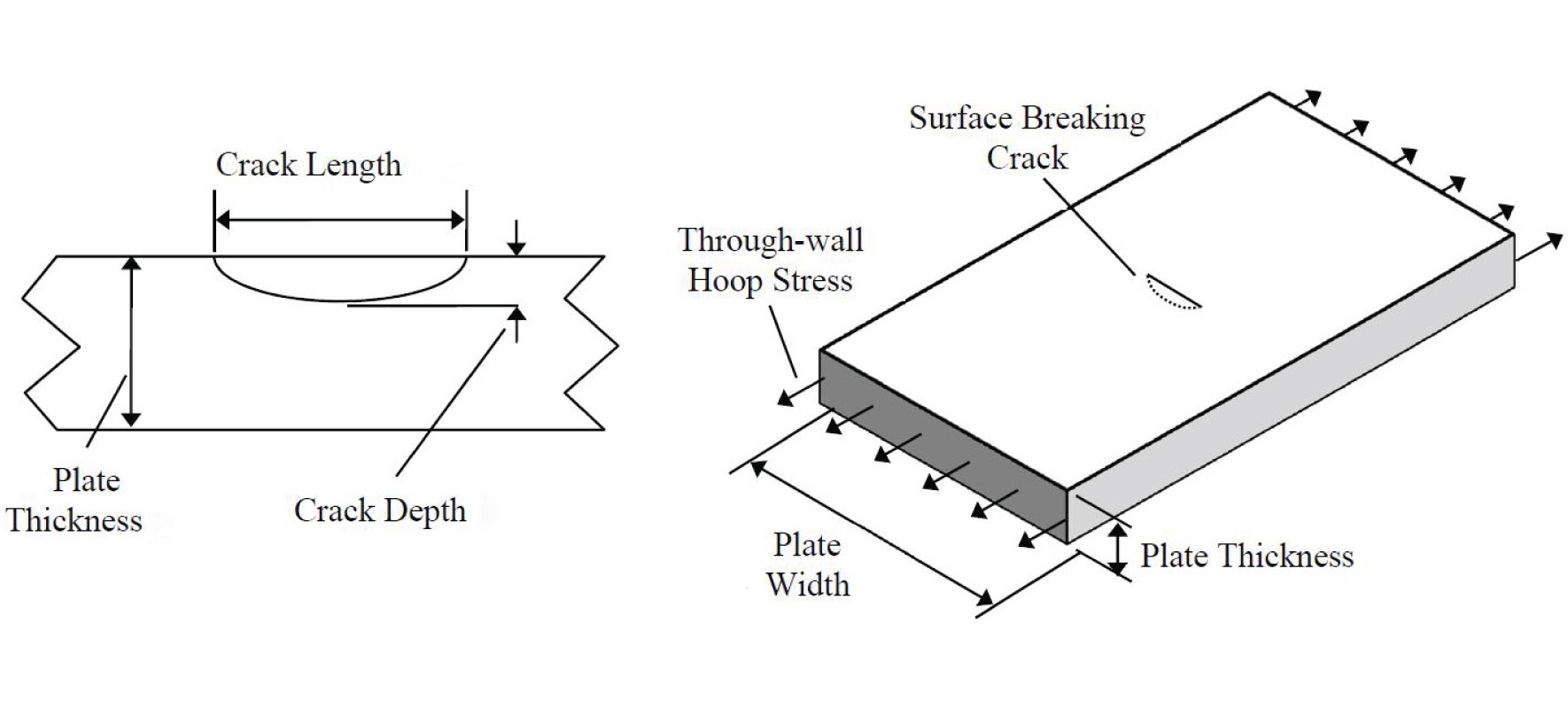

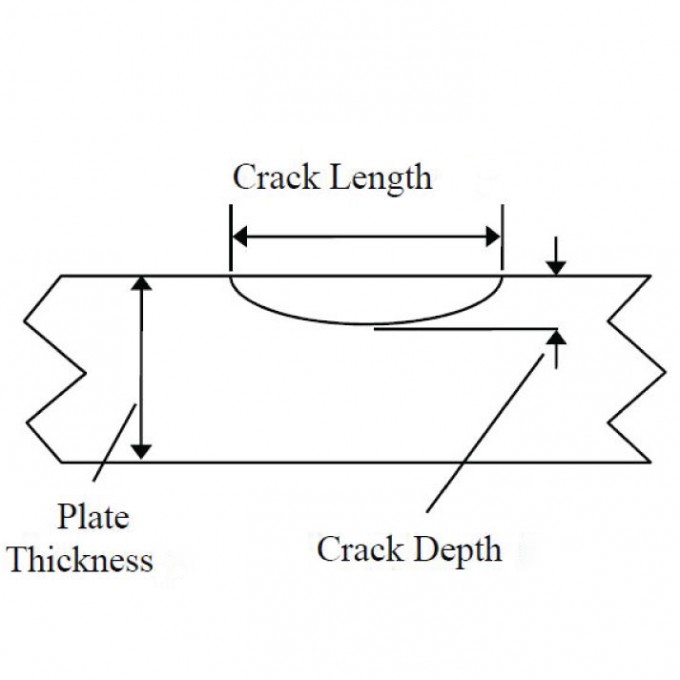

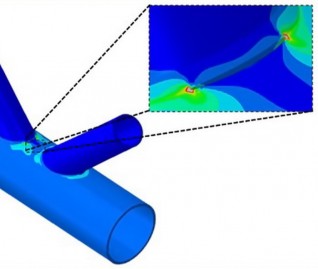

Surface-breaking flaws of prescribed length and depth were modeled using linear elastic fracture mechanics principals to evaluate the tendency of material failure due to both fracture and plastic collapse on a failure assessment diagram. The evaluation included the influence of stress concentration effects at discontinuities (e.g., tray supports) and residual stresses at the welded joint. Material toughness values were estimated using guidance in API 579 for austenitic stainless steel materials.

The assessment predicted relatively large maximum allowable crack sizes based on anticipated loading conditions. Long surface cracks, well in excess of those identified in the inspection, were acceptable at depths up to half-wall, with shorter flaws acceptable to through-wall. The FFS assessment demonstrated that the weld undercut defects could be safely left in place without repairs. Although significant cyclic loading was not anticipated, WJE recommended periodic inspection for sub-critical crack growth.

RELATED INFORMATION

-

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics

Our metallurgical and applied mechanics engineers provide solutions related to design... MORE >Services | Metallurgy and Applied Mechanics -

WJE fracture mechanics consultants have provided fracture mechanics assessment and fitness for... MORE >Services | Fracture Mechanics Assessment and Fitness for Service

WJE fracture mechanics consultants have provided fracture mechanics assessment and fitness for... MORE >Services | Fracture Mechanics Assessment and Fitness for Service -

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy

We provide dedicated engineering support and specialized testing services for all sectors across... MORE >Markets | Energy