WJE PROJECTS

Parmly Billings Library

CLIENT |

Will Bruder + Partners Ltd. |

LOCATION |

Billings, MT |

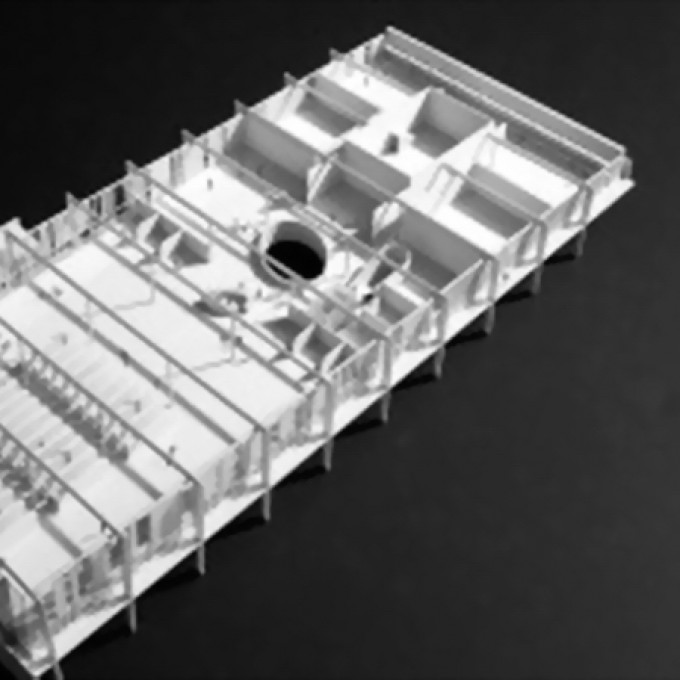

Thermal Break Analysis for Structural Steel Beams

The initial objective of this assignment was to determine the potential for condensation to develop within the interstitial space of the second floor resulting from the extension of the structural steel frame beyond the thermal envelope of the building's facade. A follow-up study was also performed to determine appropriate strategies and to identify specific products that could be incorporated to mitigate these risks.

BACKGROUND

WJE was retained by the architect of record, Will Bruder + Partners Ltd., to evaluate the risk of condensation resulting from structural steel beams that extended outside the building's thermal envelope and to evaluate possible remediation strategies.

SOLUTION

A model of the original design conditions was created in THERM, a finite element analysis program that simulates two-dimensional heat transfer. This allowed confirmation, based on anticipated interior and exterior conditions, that the surface of the steel beam within the interstitial space of the floor assembly would reach the dew point temperature of the inside air resulting in condensation. The model was modified to include the application of closed-cell spray foam insulation over various lengths of the beam as a means to mitigate this issue. While this approach could have been used to prevent condensation on the beam itself, it did not address the effects of the thermal bridge created by the beam on the supported floor slab assembly. In addition to requiring the extensive use of spray foam and creating various constructability concerns, this approach would not have provided a comprehensive solution to the problem.

Based on these findings, WJE conducted research into available structurally rated thermal break systems. Working with the project's structural engineer an appropriate product was identified and the THERM model again revised to determine the performance of the system with the addition of this thermal break. Ultimately, a resin-based thermal break was incorporated into the structural design and, in conjunction with the limited use of spray foam within the interstitial space, the required thermal performance was achieved.

RELATED INFORMATION

-

Clients turn to us when they need a firm that fully understands the aesthetic and functional... MORE >Services | Building Enclosures

Clients turn to us when they need a firm that fully understands the aesthetic and functional... MORE >Services | Building Enclosures -

Our building science expertise and resources are the result of a commitment to understanding the... MORE >Services | Building Science

Our building science expertise and resources are the result of a commitment to understanding the... MORE >Services | Building Science -

When the integrity or condition of a structure is in question, clients rely on us for answers MORE >Services | Structural Engineering

When the integrity or condition of a structure is in question, clients rely on us for answers MORE >Services | Structural Engineering