WJE PROJECTS

Flue Gas Desulfurization Process

CLIENT |

Coal-Fired Electric Power Plant |

LOCATION |

Midwest |

Assessment of Synthetic Gypsum Produced at a Coal-Fired Power Plant

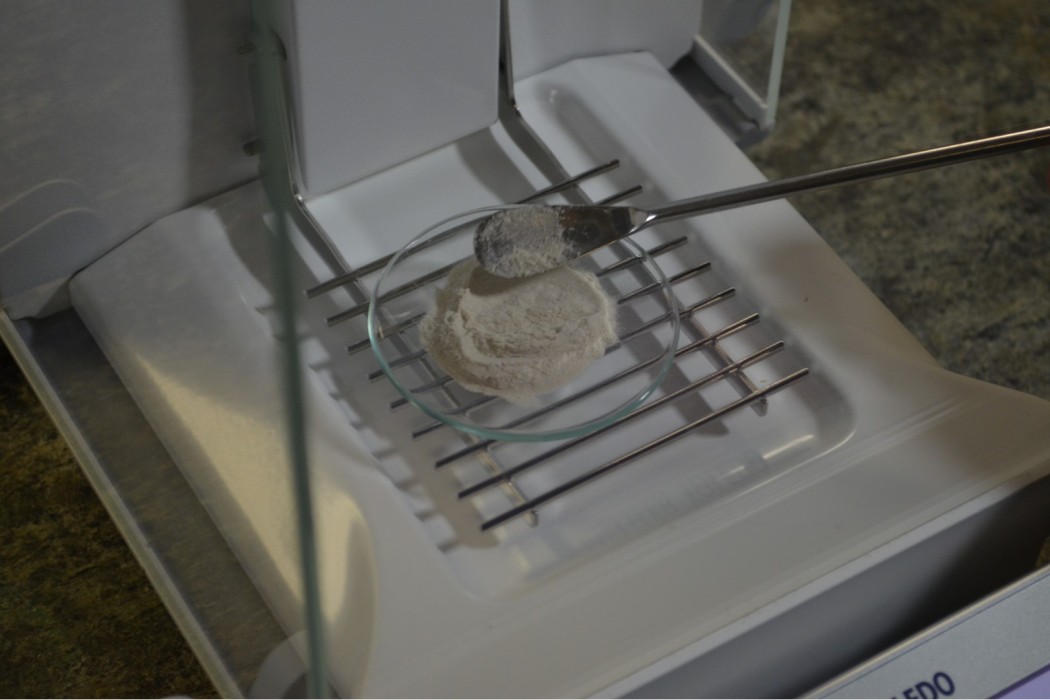

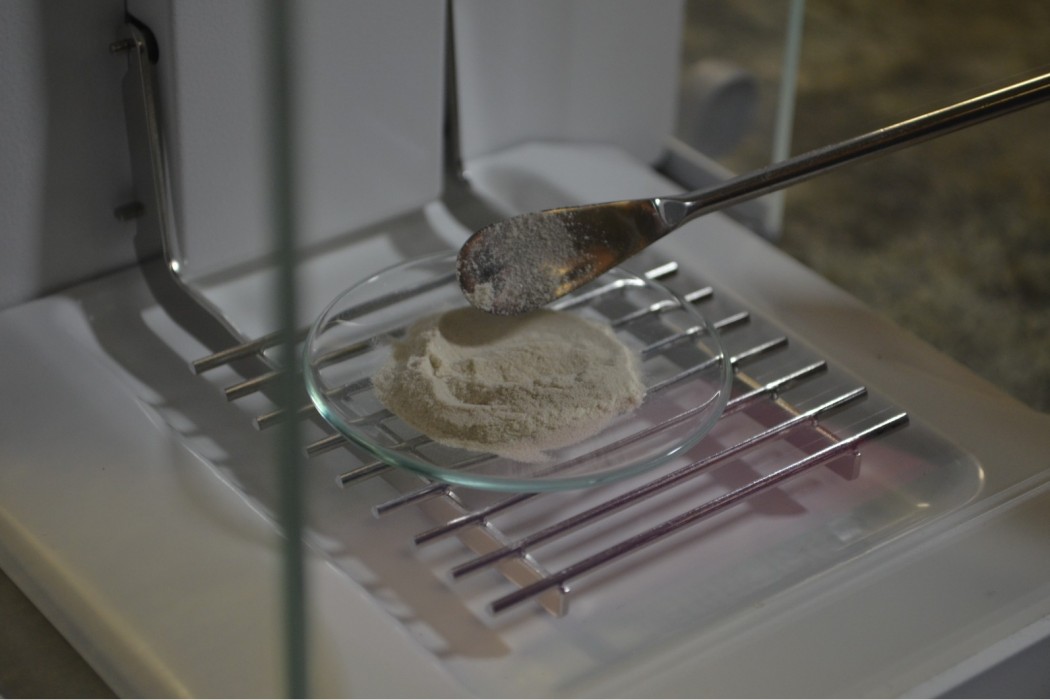

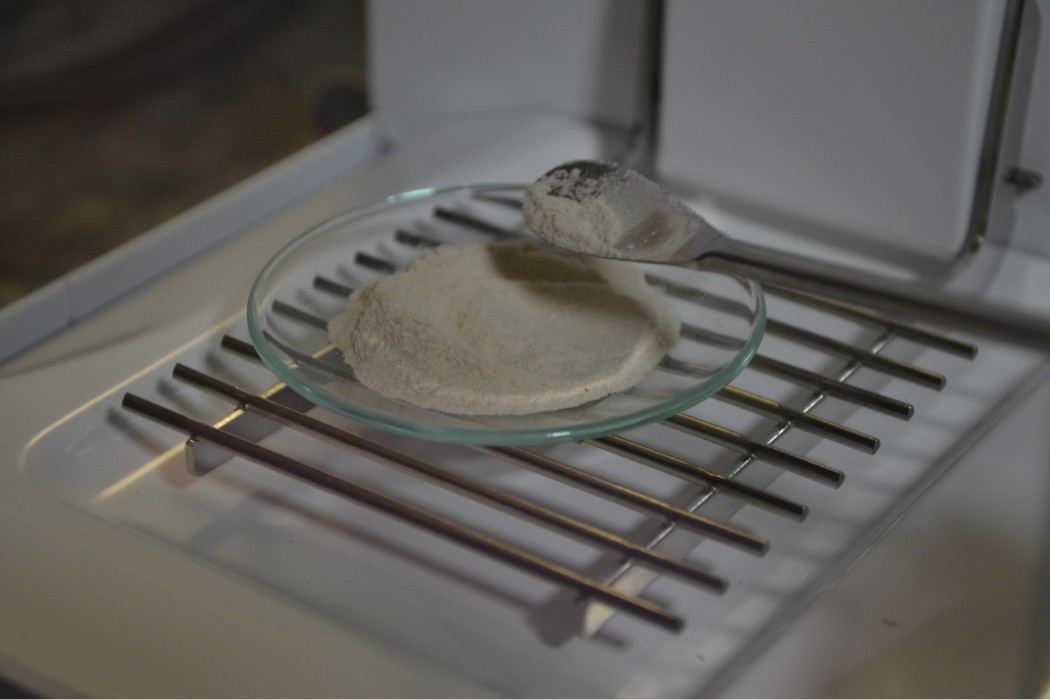

WJE was retained by a coal-fired power plant to assess the performance of their flue gas desulfurization (FGD) system and to evaluate the synthetic gypsum produced during this process. The purpose of the gypsum evaluation was to provide characterization of selected chemical and physical properties with respect to its acceptance for use in drywall manufacturing.

BACKGROUND

Numerous coal-fired electric power plants are using a flue gas desulfurization (FGD) process to remove sulfur dioxide from the gas stream in order to reduce air pollution. FGD or synthetic gypsum generated as a byproduct of this process, commonly known as scrubbing, has characteristics similar to natural gypsum, making it an environmentally desirable source for drywall production. Chemical and physical properties of synthetic gypsum are evaluated as part of acceptance testing to assure that the product meets existing specifications and guidelines.

SOLUTION

WJE was retained to assess the efficiency of the flue gas desulfurization process and the quality of the produced synthetic gypsum. The effectiveness of the scrubbing process and its impact on emissions reduction was monitored by testing samples collected from various stages of the process. Samples of limestone, gypsum slurry or cake, processed and waste water were tested following recommendations and guidelines of Electric Power Research Institute (EPRI). The quality of synthetic gypsum is also assessed as a part of the evaluation of the scrubbing process efficiency. Factors such as free moisture content, residual carbonates, fly ash content, silicon dioxide content, calcium sulfite content, and soluble salt content directly affect the purity of the synthetic gypsum and its suitability as raw material for drywall production. WJE provided various analytical services including differential scanning calorimetry, thermogravimetric analysis, ion chromatography, x-ray diffraction and scanning electron microscopy for synthetic gypsum characterization. The results of the testing indicated that synthetic gypsum produced by the utility company was of high purity and met all the specifications requirements of the drywall manufacturer.

RELATED INFORMATION

-

Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing

Our materials scientists provide comprehensive consulting services for the evaluation and... MORE >Services | Materials Evaluation and Testing -

WJE was founded on a spirit of innovation—that everything can be improved and that... MORE >Services | Product Development, Evaluation, and Testing

WJE was founded on a spirit of innovation—that everything can be improved and that... MORE >Services | Product Development, Evaluation, and Testing -

Clients rely on our experience and laboratory capabilities to develop innovative solutions to... MORE >Services | Materials Engineering

Clients rely on our experience and laboratory capabilities to develop innovative solutions to... MORE >Services | Materials Engineering